Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

FAQs

How does RT Manufacture achieve ultra-precise machining with ±0.002mm accuracy?

We utilize five-axis machining centers with real-time thermal deformation and tool wear compensation. Critical process CPK values ≥1.67, validated through AS9100 aerospace certification.

Can you machine micro-deep holes with aspect ratios >20:1?

Equipped with Swiss turning centers, we deliver:

Hole diameter: 0.1mm ±0.003mm

Straightness ≤0.005mm within 20mm depth

Surface roughness Ra0.2μm (medical-grade standards)

Successfully machined 0.15mm internal cavities for minimally invasive surgical instruments.

How do you enable continuous 24/7 machining operations?

Our distributed production system ensures uninterrupted day-night machining cycles, achieving 23% higher efficiency than industry averages in 2023.

What are RT Manufacture’s CNC machining capabilities?

We deliver rapid milling and turning for small batches (1-200 units) within 3-7 business days. Contact our representatives for volume pricing.

What materials do you offer?

RT provides a wide range of standard plastics and metals. Review our material inventory list for milling/turning options. We also accept client-supplied materials for custom projects.

What are your minimum/maximum machinable dimensions?

To date, we have not encountered CNC machining dimensions beyond our capabilities. Contact our engineering team for specific size requirements and technical validation.

How do you achieve 0.05mm precision in ultra-thin sheet metal forming?

We utilize servo-hydraulic compensation technology to achieve ±0.05mm flatness in stainless steel processing with thicknesses of 0.2-0.5mm, validated by the VDI 3400 standard.

How do you ensure consistency in non-standard hole arrays?

Our multi-head laser cutting system guarantees:

Hole diameter accuracy: ±0.03mm

Hole spacing repeatability: 0.02mm

Support for honeycomb/gradient hole patterns.

Are your sheet metal fabrication costs high?

Pricing depends on part complexity and geometry. To obtain an accurate cost estimate, contact our customer representatives for a complimentary quotation within hours.

What sheet metal materials do you offer?

We stock various metals including stainless steel, aluminum, copper, and brass. View the complete list of available materials for sheet metal fabrication.

What are your tolerance control standards? Can they meet high-precision requirements?

We adhere to the ISO 20457-2018 injection molding tolerance standards, categorized into three precision levels based on material properties:

Precision Grade: ±0.05mm

Commercial Grade: ±0.1mm

General Grade: ±0.2mm

For high-precision demands, we utilize Moldflow analysis to predict shrinkage rates and integrate closed-loop temperature control systems, achieving tolerances as tight as ±0.02mm (subject to material fluidity evaluation).

Are your materials internationally certified (e.g., RoHS, FDA)? How is this verified?

All raw material suppliers must provide batch-specific SGS reports (e.g., RoHS 10-substance, FDA 21 CFR compliance). Our in-house laboratory conducts quarterly inspections for heavy metals (Pb/Cd/Hg) and plasticizers (e.g., DEHP) using high-performance liquid chromatography (HPLC). For details, contact our customer representative.

How do you ensure quality consistency during mass production?

We employ Statistical Process Control (SPC) to monitor critical parameters:

Injection pressure: ±1.5%

Mold temperature: ±2°C

Cpk values ≥1.67 are verified via 2-hour sampling. First and last production samples are sealed for traceability, and clients may request remote video inspections.

As a professional component manufacturer, we are committed to providing high-precision, high-quality custom machining services for various industries. Our manufacturing standards cover four core processes: CNC machining, sheet metal fabrication, silicone molding, and injection molding. Each process utilizes advanced equipment and a rigorous quality control system to ensure that every step, from design to finished product, meets the highest industry standards. Whether it's precision parts with complex structures or the demands of mass production, we can meet your diverse needs with efficient and reliable manufacturing capabilities, helping your products stand out.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

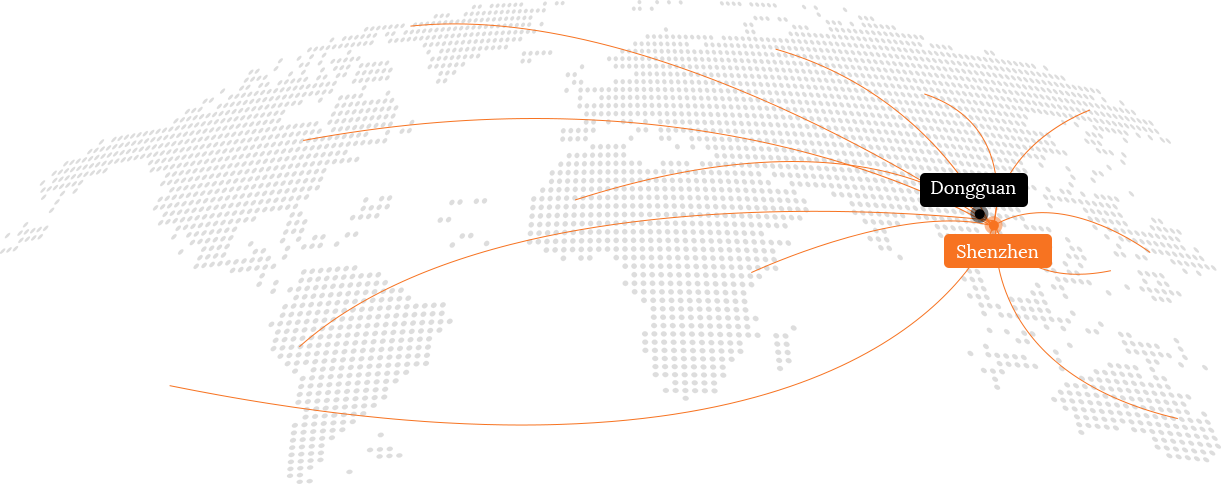

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us