Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

Injection Molding

What are your tolerance control standards? Can they meet high-precision requirements?

We adhere to the ISO 20457-2018 injection molding tolerance standards, categorized into three precision levels based on material properties:

Precision Grade: ±0.05mm

Commercial Grade: ±0.1mm

General Grade: ±0.2mm

For high-precision demands, we utilize Moldflow analysis to predict shrinkage rates and integrate closed-loop temperature control systems, achieving tolerances as tight as ±0.02mm (subject to material fluidity evaluation).

Are your materials internationally certified (e.g., RoHS, FDA)? How is this verified?

All raw material suppliers must provide batch-specific SGS reports (e.g., RoHS 10-substance, FDA 21 CFR compliance). Our in-house laboratory conducts quarterly inspections for heavy metals (Pb/Cd/Hg) and plasticizers (e.g., DEHP) using high-performance liquid chromatography (HPLC). For details, contact our customer representative.

How do you ensure quality consistency during mass production?

We employ Statistical Process Control (SPC) to monitor critical parameters:

Injection pressure: ±1.5%

Mold temperature: ±2°C

Cpk values ≥1.67 are verified via 2-hour sampling. First and last production samples are sealed for traceability, and clients may request remote video inspections.

What is your minimum order quantity (MOQ)? Are small-batch orders cost-prohibitive?

Standard MOQ is 500 pieces (for standard molds). For small batches, we apply cavity optimization and rapid mold change strategies to reduce per-unit costs by 30%. Shared mold programs eliminate MOQ restrictions (only material + processing fees apply).

How is mold lifespan evaluated? Who covers repair costs for damage?

Mold lifespan is classified by cycles:

Class 101: >1 million cycles

Class 102: >500,000 cycles

IoT-embedded sensors monitor real-time wear. Repair costs are allocated by responsibility:

Design flaws: Covered by us

Client-caused damage: Billed at cost Post-repair, molds receive a 30,000-cycle warranty extension.

Does your surface treatment (e.g., sandblasting, plating) meet corrosion resistance standards?

Plating: Minimum 8μm thickness (72-hour salt spray testing, zero corrosion).

Sandblasting: Ra 0.8–3.2μm (customizable).

Third-party certifications (e.g., ASTM B117 salt spray tests) are available. Complimentary protective coatings (e.g., Parylene vacuum coating) are offered.

Do you offer cost-saving material alternatives?

We provide a performance-cost matrix for substitutions, such as:

ABS alternative: PP + 20% glass fiber (18% cost reduction, 30% higher tensile strength).

PC alternative: TRITAN™ (food-grade, comparable impact resistance, 25% cost reduction).

A material change Disclaimer agreement is required.

How do you prevent design defects (e.g., shrinkage, warpage)?

Defects are mitigated via Design of Experiments (DOE):

Shrinkage: Hold pressure increased to 85% injection pressure; cooling time extended to wall thickness² × 1.5 s/mm.

Warpage: Mold temperature variation controlled within ±5°C; ribs added (thickness ≤60% of the main wall).

Free Design for Manufacturability (DFM) reports include CAE simulation visuals.

Do you provide full-dimensional inspection reports (FAIR)? What is your equipment's accuracy?

Yes. We use coordinate measuring machines (CMM, accuracy: 0.001mm) and blue-light scanners to generate AIAG PPAP-compliant reports. Clients may designate 3 critical dimensions for complimentary additional testing.

How do you protect parts during packaging and shipping?

Anti-static EPE layered packaging (ASTM D257 compliant).

Heavy parts: Wooden crates + honeycomb cushioning (ISTA 3A certified).

Do you allow mold ownership transfer or sharing?

Three options are available:

Exclusive ownership: 100% mold prepayment + 5% annual storage fee.

Shared molds: 50% prepayment, no storage fees for future orders.

Third-party transfer: 30% net mold value transfer fee.

Molds will destroyed post-contract (video proof provided).

As a professional component manufacturer, we are committed to providing high-precision, high-quality custom machining services for various industries. Our manufacturing standards cover four core processes: CNC machining, sheet metal fabrication, silicone molding, and injection molding. Each process utilizes advanced equipment and a rigorous quality control system to ensure that every step, from design to finished product, meets the highest industry standards. Whether it's precision parts with complex structures or the demands of mass production, we can meet your diverse needs with efficient and reliable manufacturing capabilities, helping your products stand out.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

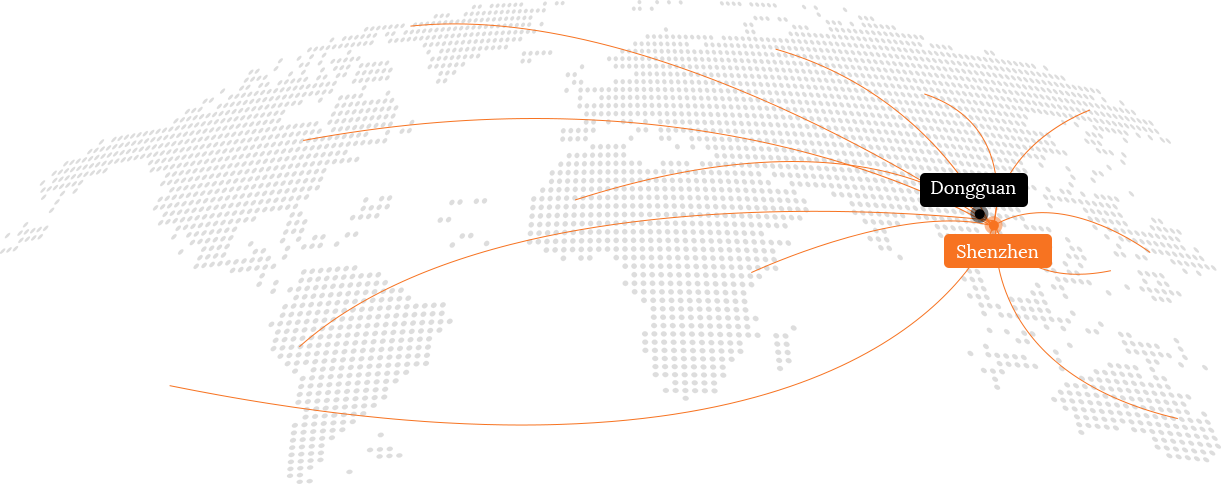

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us