Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

Parts Quality Certification

In modern industrial production, parts quality certification is a key link to ensure the overall performance and reliability of products. It is a rigorous and systematic process that covers multiple processes from raw material inspection to production process monitoring to finished product performance evaluation.

Only after a series of rigorous tests and all data meet the standards can parts obtain quality certification. This allows them to be safely used in various high-end equipment and precision instruments, providing strong guarantees for the high-quality development of industrial manufacturing.

Over the years, we have made great efforts to actively control the quality process and obtain recognition and certification from well-known organizations to prove our commitment to quality and excellence.

We Take Every Step of Parts Manufacturing Seriously

Only through strict process controls and standardized operations can we consistently deliver parts that meet our customers' exact specifications.

01

Technical Analysis

Our quotation engineers will conduct a detailed manufacturing analysis of drawing parts based on usage requirements, functional requirements, etc., and determine their size, shape, material, and various performance indicators. Usually, we need customers to provide accurate 2D design drawings and 3D models.

02

Process Planning

Our CNC programmers will analyze the characteristics of the parts in detail and develop a suitable processing and manufacturing process route, such as determining whether to use injection molding, sheet metal fabrication, CNC machining, or other process methods for production, as well as the sequence of each process link.

03

Raw Material Preparation

Purchase the corresponding raw materials according to the design requirements and inspect their quality and specifications to ensure that they meet the basic conditions for subsequent production, such as inspecting the hardness and purity of steel.

04

Mold And Fixture Preparation

Suppose the production process involves specific mold forming or requires fixtures to assist positioning, clamping, and other operations. In that case, it is necessary to design, manufacture or purchase in advance, and debug in place to ensure that it can be used normally.

05

Equipment Debugging And Personnel

Debug all kinds of processing equipment and testing equipment that will be used to produce the parts to ensure that they are in the best working condition; at the same time, arrange operators with corresponding skills according to the production task volume and process complexity.

06

Quality Plan Formulation

Clearly define the quality control standards and inspection methods for each production link, and determine the specific requirements and operating specifications for different stages such as first-piece inspection, patrol inspection, and finished product inspection to ensure that the parts produced meet quality expectations.

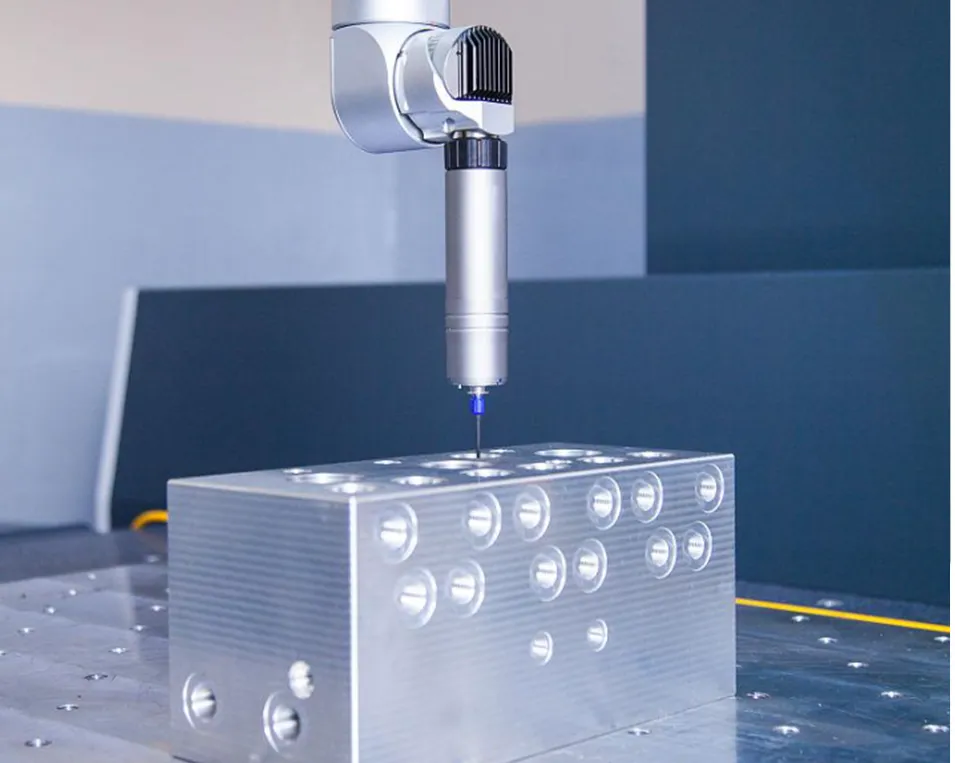

Our Advanced Metrology Equipment for Parts

RT and our parts manufacturing suppliers utilize the latest metrology equipment to ensure part precision and accuracy

Plug Gauges

Height Gauges

Optical projector

Metal Thickness Gauge

Ring and Thread Gauges

Various Micrometers and Calipers

Coordinate measuring machine (CMM)

Mass Spectrometers (XRF) Machines for Material Composition

Precision Assured

Our quality control system combines essential tools with advanced verification capabilities:

Digital Calipers & Hardness Testers for daily batch checks (±0.05mm tolerance)

CMM (Coordinate Measuring Machine) for critical dimension validation (automated GD&T reporting)

Surface Roughness Testers with Ra/Rz measurement

Optical Comparators for Profile Verification

All CMM programs are validated against ISO 10360 standards, providing 3D measurement accuracy within ±1.5μm. While maintaining monthly calibration cycles, we prioritize operator training to ensure repeatable results across 500+ annual production batches. Both metric and imperial unit systems are supported.

Part Quality Documentation

We provide quality documentation reports for all parts manufacturing projects. We can also provide inspection reports, material certification, and compliance documents.

Part Quality Documentation

We provide quality documentation reports for all parts manufacturing projects. We can also provide inspection reports, material certification, and compliance documents.

Part Visual Inspection

We will verify that each part product meets the customer's color, texture, and overall appearance standards.

Dimension Inspection

For part dimension inspection, for simple structures, we will use vernier calipers, micro calipers, and height gauges; for complex part data, we use projector equipment or CMM machines to ensure accurate measurement.

Performance Inspection

After the part is produced, we will carefully check all the performance of the parts to ensure that parts such as threaded holes are installed correctly during assembly.

Inspection Report

After the inspection, we will write the data obtained from the part test into an inspection report truthfully, and explain all the inspection processes and results in detail.

RoHS Report

We will provide you with a RoHS report upon your request to confirm whether the material complies with the RoHS standard.

Mold Flow Analysis Report

We will provide you with a mold flow analysis report upon your request to ensure part quality issues.

Machining Parts Manufacturing By RT

From automotive parts to aerospace components, we have been manufacturing products that our customers praise. Here are some of our finished products.

See What Our Customers Say

Customers' real evaluation is our driving force, and customer satisfaction is our service goal.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

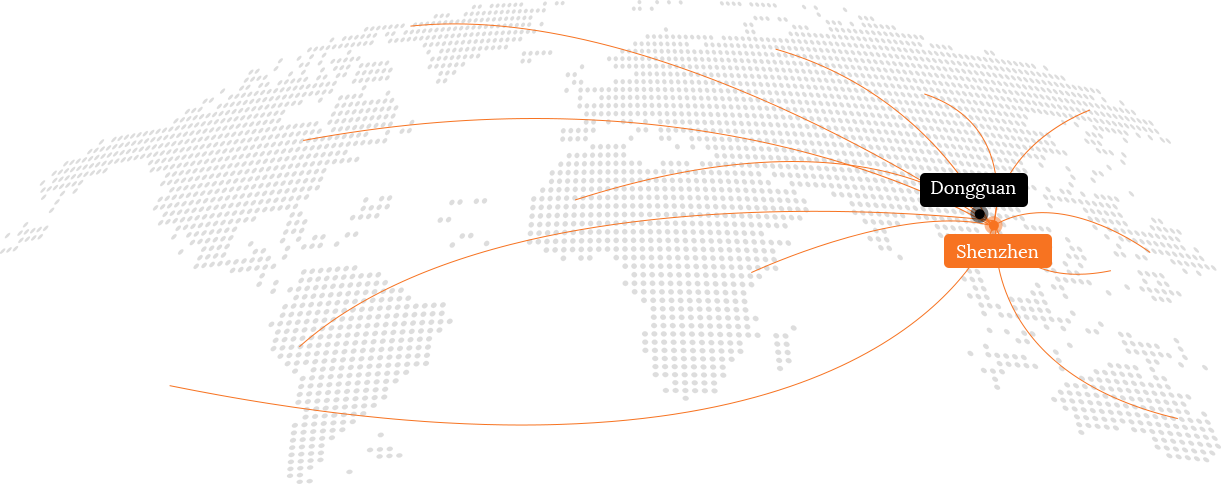

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us