Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

Our Vacuum Casting Services

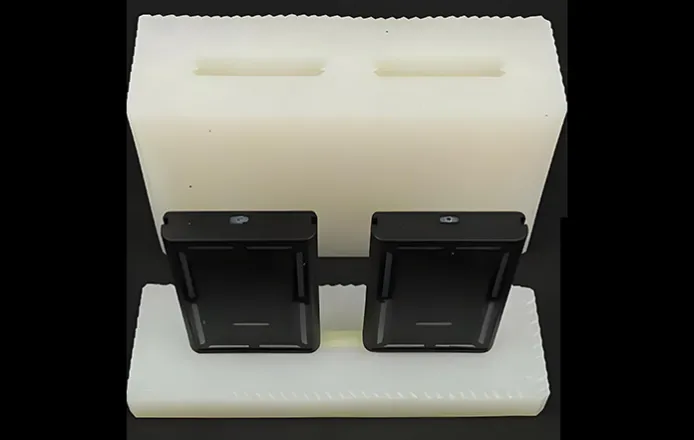

At RT, we offer two vacuum manufacturing solutions, polyurethane vacuum casting and vacuum forming. Polyurethane vacuum casting, also known as silicone molding, is an economical alternative to injection molding for small batch production, often suitable for high-quality prototypes, functional testing, concept verification and other use scenarios.

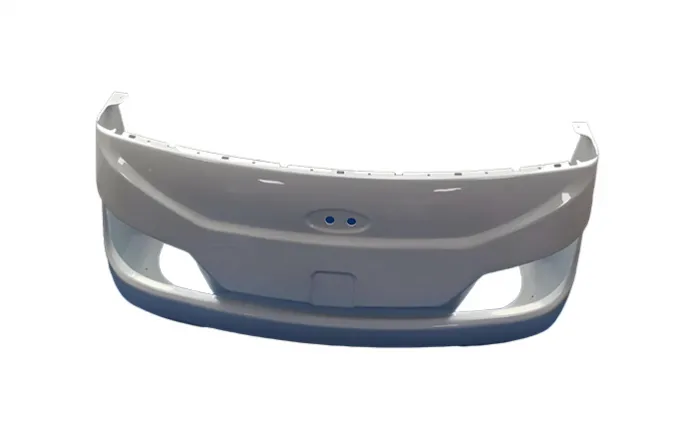

Vacuum Forming

Vacuum forming is a plastic processing technology that is mainly used to manufacture plastic packaging and other plastic products. This is a technology that heats and softens a flat plastic hard sheet, uses a vacuum to absorb it on the mold surface, and then cools it to form. Vacuum forming technology is widely used in plastic packaging, lighting, advertising, decoration, and other industries.

Our Vacuum Casting Capabilities

We have three quality certification systems (ISO 9001:2015, ISO 13485, IATF 16949:2016) to ensure the accuracy and durability of each of your silicone molded parts.

In terms of quality, we use the highest standards to manufacture your vacuum cast parts, including product wall thickness, surface finish, etc.

In terms of efficiency, each of our vacuum silicone molds can be reused about 20-30 times, allowing parts to be created quickly and easily.

In terms of manufacturing range, we can cast parts of any shape and size for you, from headphones to 2-meter-long car bumpers.

In terms of manufacturing tolerances, our strict tolerance control is ±0.03 to ±0.05 mm, which is enough to meet any manufacturing tolerance requirements in the world.

The fastest delivery time is only 5 days.

Silicone Molding & Vacuum Forming FAQ

Can you produce silicone parts compliant with medical/food contact standards?

We hold ISO 13485 medical certification and FDA 21 CFR 177.2600 food-grade compliance. All medical silicone molding utilizes biocompatible LSR material (Shore A 10-80 hardness available), while vacuum-formed trays use RoHS-compliant PETG/APET (migration test ≤0.1ppm), suitable for medical device packaging and food containers.

Do you accept small-batch orders (e.g., 100 units)? What is your MOQ policy?

We specialize in low-volume flexible production! Silicone molding starts at 50 units MOQ (compression molding), and vacuum forming at 100 units MOQ (rapid aluminum tooling change). Our modular mold design reduces initial tooling costs, ideal for prototype validation and pilot runs.

What precision tolerance can silicone parts achieve? How do you control deformation?

Through vacuum casting technology and temperature-controlled vulcanization, we achieve ±0.05mm dimensional tolerance (ISO 2768 standard). For thin-walled components (e.g., gaskets), fiberglass-reinforced molds and post-curing processes minimize shrinkage, ensuring high dimensional stability.

What ESD (anti-static) solutions do you offer for vacuum forming?

We provide three-tier ESD protection:

Material-level: Permanent static-dissipative PETG (surface resistance: 106-109 Ω/sq);

Structural-level: Integrated conductive snaps + grounding copper foil channels;

Certification: Compliance with ANSI/ESD S20.20, ideal for PCBA electronic trays.

How long do silicone molds last? Can they replicate fine details?

Molds made with German-imported silicone (Shore A 40 hardness) yield 200-300 cycles (varies by complexity). We replicate micro-textures (Ra 0.1μm) and undercut structures with high fidelity.

How do you ensure strength for demanding applications (e.g., automotive vacuum-formed parts)?

For structural requirements:

Material upgrade: ABS/PC alloy sheets (impact resistance >50 kJ/m²);

Process enhancement: High-pressure forming (6-8 Bar) + rib topology optimization;

Post-treatment: Ultrasonic welding or epoxy reinforcement.

Does your lead time include mold fabrication?

Standard lead times: 15 days for silicone molding (includes 7 days mold making), 20 days for vacuum forming (includes 10 days CNC aluminum tooling).

What is your quality dispute resolution process (e.g., bubbles/thickness variation)?

Our commitment:

First-article inspection report (CMM dimensional check + airtightness test);

Batch issue compensation: 72-hour response, free re-production;

Prevention systems: Vacuum degassing units for silicone molding and infrared thickness gauges for thermoforming, with real-time defect detection.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us