Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

Vacuum Casting

What are your tolerance standards for silicone mold duplication? Can they achieve ±0.1mm accuracy?

Our standard tolerance for silicone mold duplication is ±0.3mm (per ASTM D2000). For ±0.1mm precision, we implement the following measures:

Low-shrinkage silicone: Materials with shrinkage rates <0.1% (e.g., Dragon Skin™ FX-Pro).

Multi-stage pressure control: Vacuum casting with gradient pressure (0.8–1.2 bar).

CNC machining allowances: Critical dimensions ±0.05mm post-casting machining margins.

What is the lifespan of silicone molds? What is the maximum output per mold?

Mold lifespan varies by material grade:

Standard silicone (e.g., Smooth-Sil 940): 20–30 parts.

High-performance silicone (e.g., Zhermack ZA 8): 50–100 parts.

Composite molds with metal reinforcement: Up to 200 parts.

Are small-batch orders (e.g., 50 units) feasible? How do you optimize costs?

Yes. We optimize costs through:

Mold reuse: Multiple batches within a total lifespan.

Multi-cavity layout optimization: 40% material utilization improvement.

No MOQ: Unit price = material cost ×1.15 (15% loss factor).

What level of surface detail replication can you achieve (e.g., textures, logos)?

Surface replication is classified per VDI 3400:

Class A: Ra ≤0.8μm (replicates 10μm-level textures).

Class B: Ra ≤1.6μm (general logos/patterns).

3D laser-engraved master molds: ±5μm accuracy.

How do you prevent bubbles and delamination in multi-material insert casting?

For metal/plastic inserts:

Pre-heating inserts: 80°C to minimize thermal stress.

Extended degassing: Vacuum ≤5mbar for 15 minutes.

Interface enhancers: e.g., Loctite 770 for silicone-insert bonding.

As a professional component manufacturer, we are committed to providing high-precision, high-quality custom machining services for various industries. Our manufacturing standards cover four core processes: CNC machining, sheet metal fabrication, silicone molding, and injection molding. Each process utilizes advanced equipment and a rigorous quality control system to ensure that every step, from design to finished product, meets the highest industry standards. Whether it's precision parts with complex structures or the demands of mass production, we can meet your diverse needs with efficient and reliable manufacturing capabilities, helping your products stand out.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

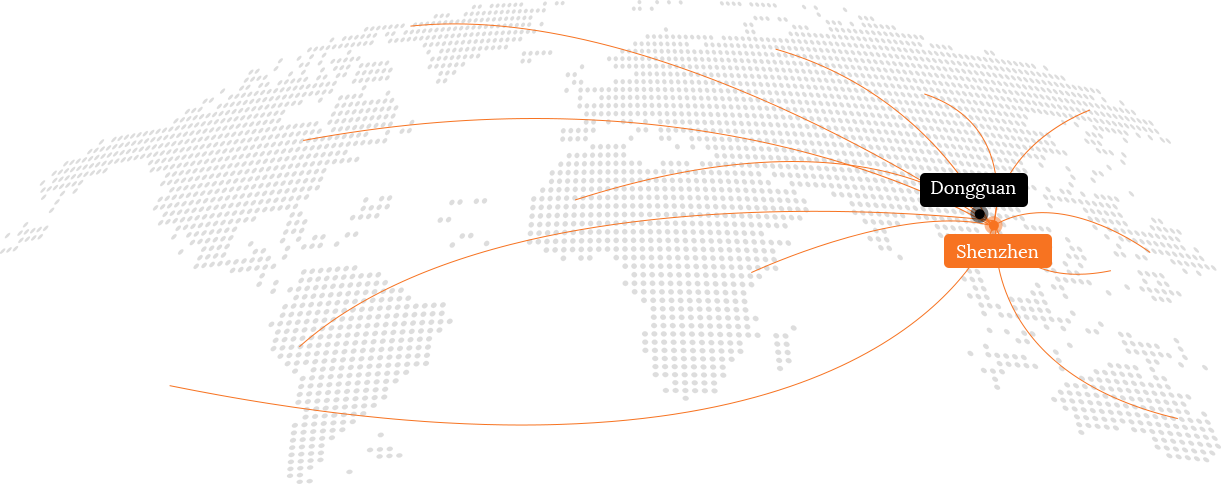

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us