Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

FAQs

How does RT Manufacture's core technological advantage ensure part precision?

We integrate five-axis machining centers with closed-loop feedback systems to predict and correct over 90% of potential errors before production. Critical dimensional tolerances reach ±0.005mm, with surface roughness Ra 3.2μm or lower, fully compliant with the highest ASME Y14.5-2018 standards.

Can you process special materials like high-temperature alloys or composites?

With ISO 13485 and AS9100 certifications, our material library covers 217 engineering materials, including Inconel 718 and carbon fiber-reinforced PEEK. Third-party material test reports and certifications are available upon request.

How do you ensure design confidentiality?

We implement military-grade data security: quantum-encrypted tunnels for file transfers, physically isolated production networks, and optional blockchain-based archival services. All employees undergo quarterly NDA compliance training, with zero data breaches recorded in the past five years.

How do you address complex surface machining challenges?

Our elite CAD/CAM programming team develops optimized toolpaths to efficiently process:

① Asymmetric turbine blades (0.1mm curvature radius)

② Micro-hole arrays (density exceeding 500 holes/cm²)

③ Freeform surfaces (G3 continuity smoothness).

Do you hold industry-specific certifications?

Beyond standard ISO certifications, we maintain:

① IATF 16949 for automotive

② ISO 13485 for medical devices, with full compliance documentation.

How do you manage technical standard differences in multinational projects?

Our engineers specialize in converting 31 international standards, including:

① DIN-JIS dimensional system conversions

② ASME-GB geometric dimensioning and tolerancing (GD&T) mapping

③ Automated RoHS/REACH substance screening for global compliance.

Can you handle oversized components?

Equipped with the largest CNC gantry machining centers (worktable: 2000 x 750 x 650mm), we process:

① Automotive wheel hubs

② Marine diesel engine blocks

③ Aerospace structural frames.

Our maximum CNC lathe capacity reaches 2000 x 860mm.

Is an NDA required to work with RT Manufacture?

NDAs are optional based on client needs. All files uploaded to our platform are protected by state-of-the-art encryption and confidentiality protocols. Contact your account representative for details.

Which industries use RT Manufacture's services?

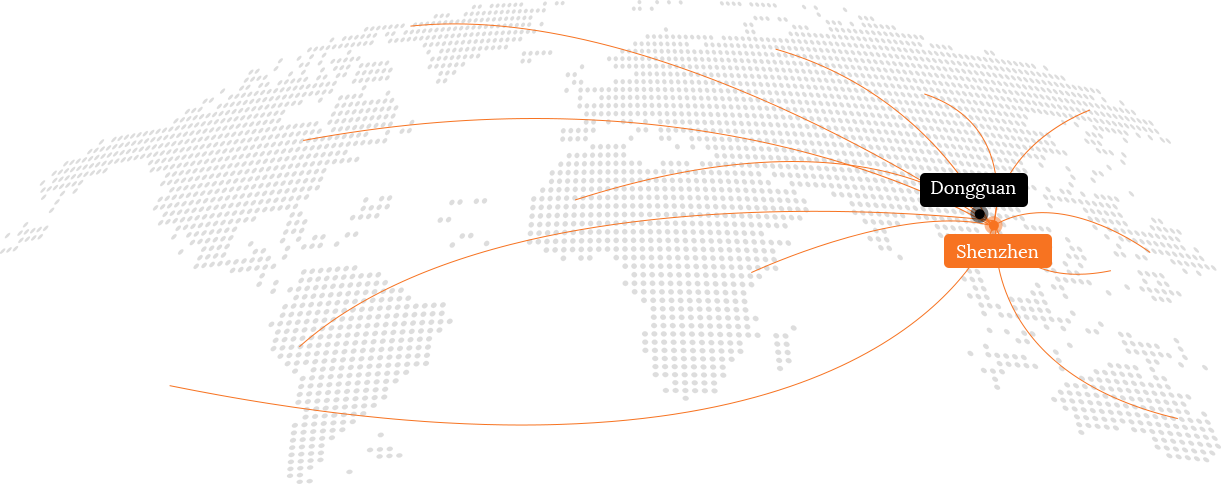

We serve global clients across: medical devices, automotive, outdoor sports, aerospace, consumer electronics, and industrial machinery sectors etc.

How many machines do you operate?

To date, we maintain over 100 machines, including milling centers, lathes, laser cutters, injection molding machines, and press brakes. This number grows continuously with our expansion.

Does RT offer finishing options or secondary processing?

All manufacturing services include enhanced finishing and secondary processes:

CNC machining, Sheet metal fabrication, Injection molding, Vacuum casting

Do you provide manufacturing solutions beyond those listed on your website?

Yes. In addition to core processes, we offer 3D printing, mold manufacturing, and customized production solutions.

Are your quotations free of charge?

Yes. All quotations are complimentary and meticulously reviewed by our experienced engineers to ensure accuracy and cost-effectiveness.

As a professional component manufacturer, we are committed to providing high-precision, high-quality custom machining services for various industries. Our manufacturing standards cover four core processes: CNC machining, sheet metal fabrication, silicone molding, and injection molding. Each process utilizes advanced equipment and a rigorous quality control system to ensure that every step, from design to finished product, meets the highest industry standards. Whether it's precision parts with complex structures or the demands of mass production, we can meet your diverse needs with efficient and reliable manufacturing capabilities, helping your products stand out.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us