Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

Our Component Manufacturing Standards

RT Manufacture Production Orders

Production orders from RT Manufacture shall adhere to the fundamental process specifications corresponding to the selected manufacturing method. Any additional requirements for machining accuracy or quality must be explicitly specified in your design drawings, procurement documents, and technical specifications.

Appearance and Surface Finish

Coating surfaces shall exhibit uniform consistency, covering all contact interfaces and adjacent areas of the component.

Finished surfaces must be free from defects, including cracks, abrasions, or structural damage.

Components formed by sheet metal cutting or stamping shall follow differentiated appearance criteria. Refer to the relevant sections for detailed guidelines.

Machining Processes and Precision Control

Critical functional surfaces must be free of stepped textures or abnormal machining marks.

All machined areas shall comply with specified roughness design criteria.

Machined surfaces shall eliminate residual tool marks, chatter marks, and process residues, and meet defined roughness parameters.

Edge Treatment Specifications

Exposed edges shall undergo chamfering to remove sharp angles, machining burrs, and metal debris.

*Secondary deburring will not be performed unless explicitly specified in the process documentation.

Cleanliness Requirements

Machined surfaces must be free of residual coolant, metal particles, foreign contaminants, or other pollutants.

Threading Standards

Thread profiles shall be fully formed and strictly conform to the precision class and tolerance ranges indicated in the drawings.

No defects, mechanical damage, or contamination is permitted in threaded areas.

Cleanliness Requirements

Machined surfaces must be free of residual coolant, metal particles, foreign contaminants, or other pollutants.

Threading Standards

Thread profiles shall be fully formed and strictly conform to the precision class and tolerance ranges indicated in the drawings.

No defects, mechanical damage, or contamination is permitted in threaded areas.

Plating Surface Requirements

Electroplated layers shall display continuous uniformity across all assembly contact surfaces.

Plated surfaces must not exhibit machining indentations, scratches, pits, blisters, or exposed substrate material.

Minor defects in non-critical areas are permissible provided they do not compromise protective functionality.

Welding Process Specifications

Welding operations shall strictly follow the technical drawings provided by the client.

Weld seams without special requirements must undergo surface cleaning to remove slag and other process residues.

Post-welding painting may only commence after the welds pass quality inspection.

Fastener Hole Standards

Positioning holes shall adopt a circular design with dimensional accuracy meeting mating component tolerance requirements.

Inner bore surfaces must be free of machining residues, chatter marks, or other process-induced defects.

Coating Quality Inspection

Sprayed coatings shall form a continuous and uniform film layer.

Coated surfaces must show no machining textures, scratches, wear, particle adhesion, flow marks, or orange peel effects.

Coating inspections shall be conducted visually at 1x magnification from an 18-inch (45.7 cm) observation distance.

Our Parts Manufacturing Standards

High Quality, Low Cost Custom CNC Machining With RT

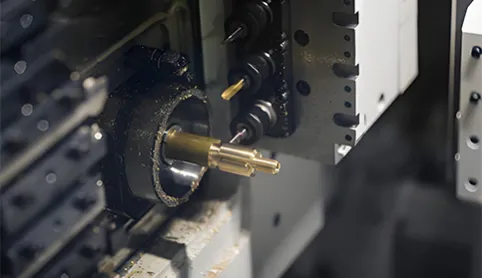

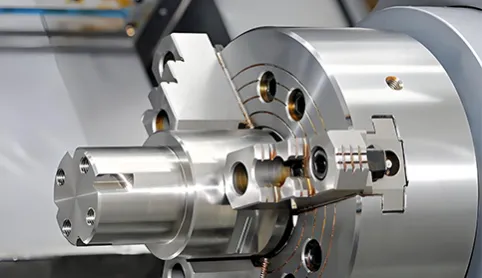

CNC Machining and Turning

Geometric features (linear dimensions/geometric tolerances) comply with ISO 2768 standards. Linear dimensions default to ISO 2768-1 medium class (m-class), with metal part tolerances of ±0.2 mm (for >6–30 mm ranges) and non-metal materials relaxed to ±0.5 mm (c-class). Special requirements must be explicitly specified.

Machined surface roughness is typically controlled within Ra 3.2 μm, with cutting textures exhibiting concentric or spiral patterns.

All sharp edges are chamfered and deburred unless explicitly marked as retained edges on drawings.

Optical-grade polymers may exhibit light-scattering effects post-machining; RT recommends polishing to enhance transmittance.

Custom CNC Turning Services

High Quality, Low Cost Custom CNC Turning Service

Sheet Metal Fabrication

Sheet Metal Fabrication

• Bending calculations use neutral layer algorithms, with standard unfolding coefficients of 0.45T. High-ductility materials require coefficient adjustments based on empirical data.

• Minimum spacing between consecutive stamped features must exceed 3× material thickness. Die clearance is maintained at 8–12% of material thickness.

• Laser-cut heat-affected zone (HAZ) width correlates positively with material thermal conductivity. Typical HAZ for 304 stainless steel is 0.15–0.3 mm.

• Flanged holes require pre-punched diameters ≥1.2× material thickness, with flange heights ≤0.8× hole diameter.

• Welding distortion compensation employs pre-cambering, reserving 0.8–1.2 mm shrinkage allowance per meter.

• All cut edges undergo default deburring. Critical edges requiring sharp retention must be specified on drawings.

Non-Standard Forming Processes

• Closed-loop rolling (closed diameter ≤5T)

• Multi-stage bending (angular tolerance <±1°)

• Compound stamping (step accuracy >IT10)

• Special-profile welding (penetration control <0.3T)

These processes initiate concurrent DFM engineering. Our technical team provides feasibility reports within 48 hours, accompanied by tiered quotations (including rapid prototyping and mass production options).

Sheet Metal Fabrication

Fast, Easy-To-Use, and satisfy customers’ individual needs

Vacuum Casting

Silicone mold replication accuracy meets CT8 class, with single-part dimensional variation of ±0.3% or ±0.25 mm (whichever is larger).

Resin flow velocity in gating systems is limited to ≤0.8 m/s to prevent turbulence-induced bubbles.

Recommended draft angles: ≥1° (standard), increasing to 3° for deep cavities with mold-release agents.

Thin-wall regions (<2 mm) require reinforcing ribs with height-to-thickness ratios ≤5:1.

Post-curing temperature gradients are controlled at 3°C/min to minimize warping

Vacuum Casting

Rapid Prototype, Rapid Tooling, Low-volume Production

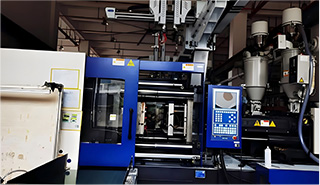

Plastic Injection Molding

Plastic Injection Molding

• Mold fabrication follows ISO 2768 with baseline tolerances of ±0.13 mm (±0.005 in). Shrinkage compensation adds ±0.05% per mm (±0.002 in per inch). Special tolerances require engineering validation.

• RT implements steel-safe margins, reserving 0.1 mm finishing allowances on functional features. Production repeatability is ±0.1 mm (±0.004 in).

• First-article delivery timelines commence upon mold acceptance. Mass production schedules are confirmed post-approval. Initial samples typically include 5–10 parts, varying with cavity layout and material properties.

Notes:

Color matching uses RAL standards; Pantone equivalents may exhibit chromatic deviations.

Quotations include default DFM requirements: draft angles ≥1°, radii ≥0.5 mm.

Gating/ejection systems follow DFM analysis recommendations.

Plastic Injection Molding

No Minimum Order Quantity — In-house Production. Consistent Quality and Guaranteed Lead Times.

Thermoforming

Heating plate temperature uniformity: ±5°C. Preheat duration: 60 seconds per mm thickness.

Forming pressure gradient: 0.2–0.8 MPa/s, with ≤5% fluctuation during dwell phase.

Cooling rate: ≤10°C/min, with auxiliary heat sinks for complex geometries.

Springback compensation is calculated using elastic modulus data. Glass-filled materials maintain ≤0.5° springback.

Multi-layer composites require intermediate venting layers with interlamellar pressure ≥0.6 MPa.

Thermoforming

Economical, efficient, and high-precision thermoforming solutions perfectly meet your project needs

Our Manufactured Parts

Our RT Thermoformed Parts Gallery and their manufacturing processes.

Case Studies

Discover why customers from around the world are choosing our vacuum casting for their component needs. Read real-life experiences and see how we\'ve met and exceeded their expectations.

New Advancements in CNC Machining Technology

Explore new advancements in CNC machining technology—5 axis, desktop CNC machines, and smart centers. Learn how custom CNC machining services boost precision for metal parts.

What’s the Difference Between CNC Machining and Sheet Metal Fabrication? | Custom Parts Guide

Learn key differences between CNC machining & sheet metal fabrication—materials, processes, costs, and applications for custom parts like automotive/medical components. Choose the right method for your needs.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

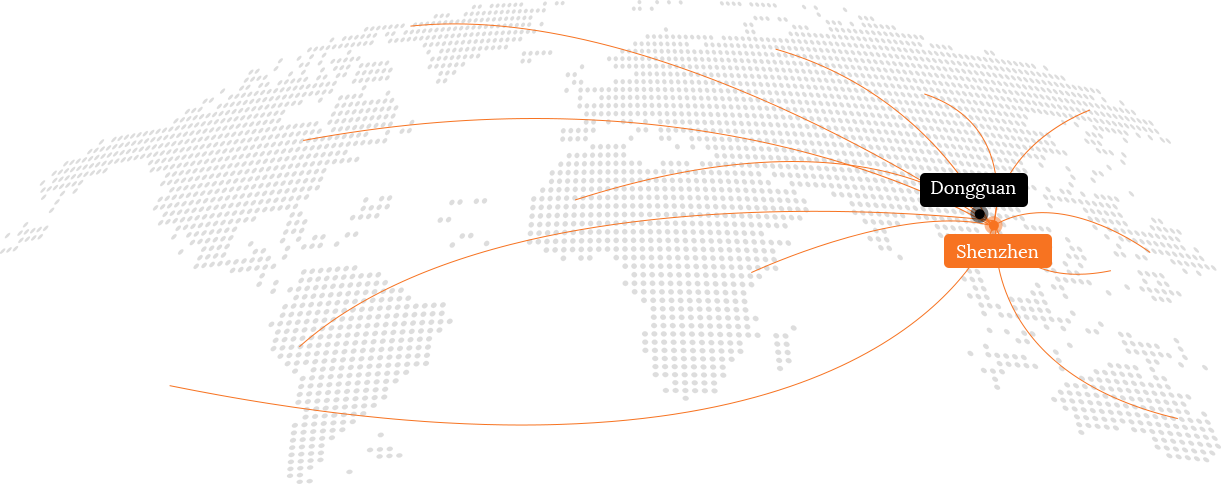

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us