Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

Our Post-processing Services

We provide comprehensive surface treatment for all machined parts. You can choose the desired surface finishing for your parts from the following post-processing processes.

Surface Treatment

Appearance treatment is a series of physical or chemical processing operations performed on the external surface of products, including electroplating, spraying, anodizing, polishing, and other processes. Its effect is remarkable. It can not only improve the aesthetics and change the color, gloss, and texture of parts but also play a protective role in preventing corrosion, wear, and oxidation. It can also improve surface properties in terms of functions, such as anti-slip and anti-fingerprint properties.

Non-aesthetic post-processing

Non-aesthetic means that the parts directly processed by these post-processing processes will still retain some processing traces.

Fine machining

Passivation

Electroplating

Chemical plating

Radium engraving

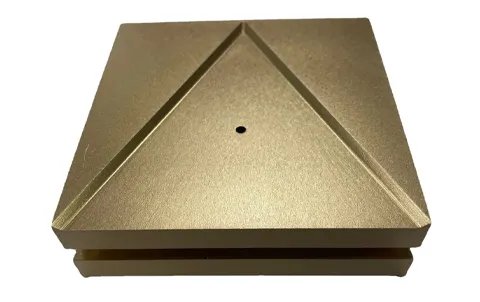

Powder coating

Blackening (black oxide)

Anodizing type III (hard coating)

Aesthetic post-processing

Aesthetic or non-aesthetic treatments can be provided according to customer requirements.

Sandblasting

Wire drawing

Wire drawing + anodizing type II

Sandblasting + anodizing type II

Sandblasting + anodizing type II + laser engraving

Sandblasting + anodizing type II + screen printing

Default aesthetic

These surface treatments usually have aesthetic effects.

Mirror polishing

Vacuum plating

Wire drawing + electrolytic polishing

Put Your Parts Into Production Today

Global Custom Parts Surface Treatment

As the world's leading supplier of parts surface treatment, we offer you a wide range of customized post-processing services. No matter where you are or what parts processing requirements you have, we can create a unique surface treatment solution for you with our excellent craftsmanship!

Cross-Industry Advantages

| Need | Our Commitment | Your Benefit |

| Save Cost | Standard processes replace premium tech | 20-40% cost reduction |

| Reduce Risk | Full inspection reports (salt spray/hardness/thickness) | 48h quality issue response |

| Save Time | Shared fixture design → <30min changeover | 72h rush delivery |

| After-Sales | Free reprocessing for process defects | 90% client retention rate |

Our Principles:

Focus on production stability, not lab specs

All data is verifiable on-site

Fair pricing with zero hidden costs

Next Step: Send drawings/samples → Get process quote + test pieces in 24h!

*All solutions use conventional equipment.

Parts Appearance Acceptability Standards

All the appearance components produced by RT Manufacture follow our appearance acceptability standards:

Consistency Standards

All components in the same batch must maintain a high degree of appearance consistency, and no differences visible to the naked eye are allowed. That is:

Color consistency

Marking consistency

Assembly consistency

Shape and size consistency

Surface texture and pattern consistency

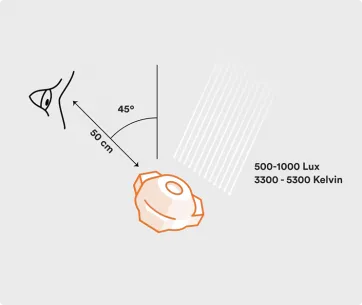

Visual Inspection Conditions

The surface quality of each part must strictly meet the following specific conditions:

Lighting conditions: The illumination is above 540LX, and the light source should be evenly distributed. It can be natural light or artificial light.

Background conditions: Generally, a black or dark background is used to enhance the contrast of surface defects of components and facilitate observation.

Observation distance: The distance between the human eye and the surface of the object to be measured is generally 15-20cm, so that the details of the component surface can be seen.

Observation angle: The inspection surface of the component should form an angle of about 45° with the desktop, and all angles, front and back, left and right, should be inspected to ensure that nothing is missed.

Observation time: For each observation surface of each component, the visual inspection time is usually not less than 5 seconds to ensure that possible appearance defects can be fully discovered.

Post-processed parts - Exhibiting Exquisite Craftsmanship

Welcome to our post-processed parts display area! Here you can find various carefully processed parts, which exhibit their unique charm. Through advanced post-processing technology, we endow the parts with excellent performance and outstanding appearance. From the surface smoothness to the detail accuracy, each part demonstrates our persistent pursuit of quality, presenting you with a feast of vision and quality and meeting your various needs for high-quality parts.

FAQs About Post-processing

All you care about is here

How do you ensure brake bracket zinc plating lasts 480h in salt spray tests without affecting assembly precision?

Reliable Process: Standard blue/white zinc plating (8-12μm) + sealer. Passes 480h salt spray test—dimensional tolerance <0.1mm (secured by fixtures).

Cost Advantage: 30% cheaper than zinc-nickel plating. Monthly capacity: 500k pcs. Supports JIT delivery.

How can surgical instruments be processed for easy cleaning without residual fluid retention?

1. Electrolytic polishing (Ra≈0.4μm) → Reduces residue by 80%

2. Passivation (nitric acid-based) → Enhances saline corrosion resistance

3. Track Record: Zero cleaning-related complaints from medical clients in 3 years.

How can threaded holes be prevented from cracking after anodizing aluminum brackets?

Insert high-temp plugs into holes before anodizing → Remove after processing

Control anodizing thickness ≤25μm (meets HB/Z 233 standard)

Result: <0.1% crack rate in 2M+ annual fastener deliveries.

How to control color variance for sandblasted & anodized earphone cases?

Uniform sandblasting grit (#180 aluminum oxide)

Dye bath temperature control (±1°C)

Output Quality: ΔE≤1.5 (visually consistent), defect rate <3%.

How to prevent washing machine panels from fading for 5+ years?

Standard phosphating + epoxy powder coating (≥60μm)

1000h UV test = 5+ years outdoor color retention

Pricing: 20% cheaper than electrophoretic coating. Monthly capacity: 200k m².

Can QPQ-treated gears withstand abrasion in mining dust environments?

Nitrided layer depth: 0.15mm → Surface hardness HV650

Field result: 3x lifespan vs. untreated gears in coal mines

Transparent Pricing: $1.1-1.7/kg (volume discounts available).

What friction coefficient can be achieved with hard-anodized robot joints?

Standard hard anodizing (40-50μm)

Dry friction coefficient ≈0.15 (50N load)

Cost-Saving Tip: Pair with graphite grease → 20,000+ service hours.

Customer Voice

Case Study

Designing for CNC Machining: Tips for Precision and Efficiency

Learn how to optimize your designs for CNC machining to reduce costs and improve quality.

CNC Machining Resources

Blogs

News

Case Studies

Guidelines

Materials

Design Guides

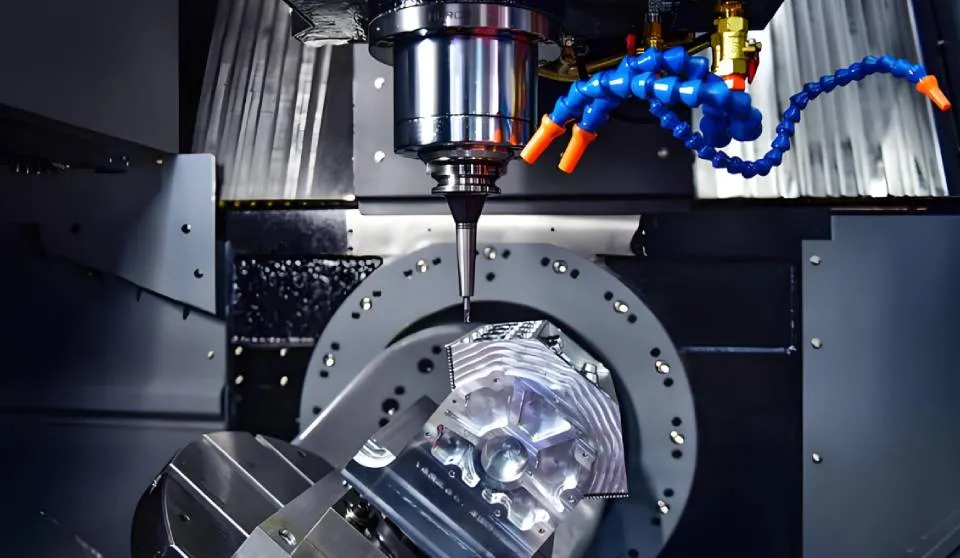

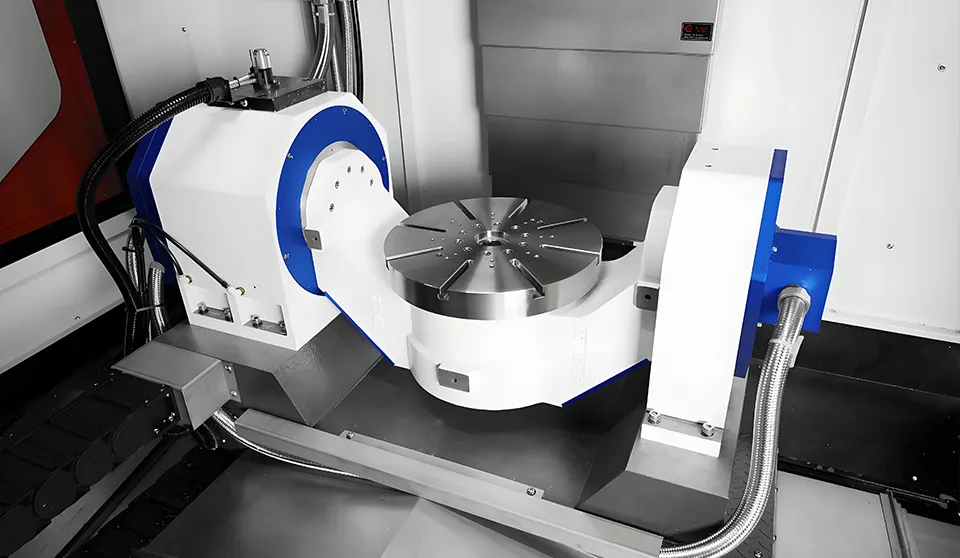

CNC Machining

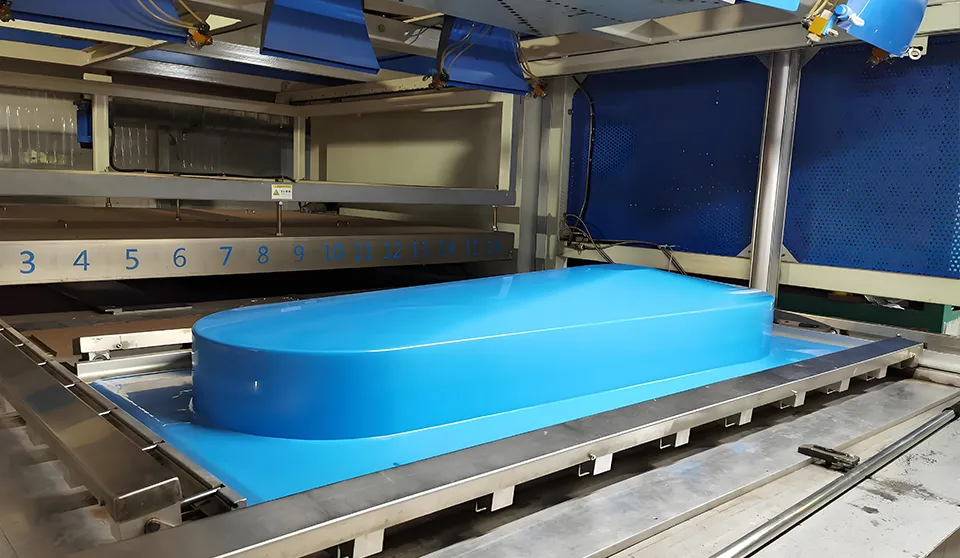

Thermoforming

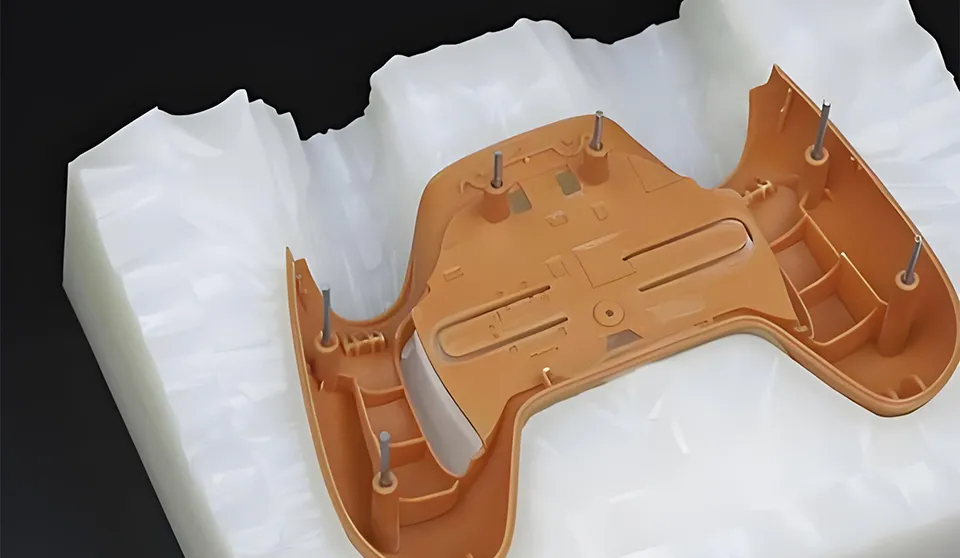

Vacuum Casting

Injection Molding

Sheet Metal Fabrication

Oct 15, 2025

What is Teflon surface treatment?

In this article, we'll break down each step of the Teflon process, detail which materials can (and can't) be Teflon-coated, and explain why this treatment technique changes the game for part surfaces.

Jul 24, 2025

That unassuming "right angle" marked on your issued drawing could secretly plant the seeds of product failure, cost explosions, or even customer claims.

Apr 20, 2025

How Does CNC Machining Drive Innovation in Automotive Parts Manufacturing?

CNC machining, with its high precision and efficiency, is reshaping the automotive parts manufacturing industry. This article will explore the applications of CNC milling and turning in the automotive sector and how they help manufacturers achieve lighter, more durable components.

Oct 29, 2025

Global Supply Chain Shifts: How Chinese Machining Suppliers Deliver Value and Reliability

Explore how China's machining sector combines advanced technology with supply chain resilience to provide precision parts and custom machining solutions in evolving global markets.

Oct 22, 2025

How Custom Part Manufacturing is Revolutionizing the Medical Equipment Industry

In the ever-evolving landscape of healthcare, medical equipment stands as the backbone of moder diagnosis and treatment.

Jun 12, 2025

The Key Role of Sheet Metal Processing in Home Appliance Manufacturing

This blog breaks down how sheet metal processing—and its related techniques like sheet metal manufacturing shape the appliances we use every day, and why it’s irreplaceable in appliance production.

Jun 30, 2025

CNC Machining Case: DJI Drone Motor Mounts

Learn about our exciting story of drone manufacturing with DJI Innovations. Our large-scale aerospace precision manufacturing can achieve monthly batch production of up to tens of thousands of units.

Jun 30, 2025

Sheet Metal Case: Schneider Electric Server Racks

Leverage our sheet metal fabrication technology to produce batches of critical sheet metal parts for a data armor giant, using 22% less material than the industry average.

Jun 30, 2025

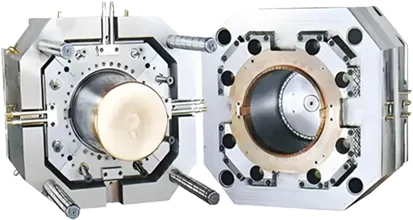

Injection Molding Case: Medtronic Insulin Pump Housings

It took us just over a month to produce exquisite injection-molded crafts, and we have produced more than one million pieces so far.

Oct 29, 2025

Navigating Tariff Wars: A Strategic Guide to Sourcing Custom Machined Parts

Facing supply chain disruptions from trade conflicts? Discover how to secure reliable custom machining solutions through strategic partnerships, regional diversification, and technical collaboration. Learn about RT Manufacture's resilient approach.

Oct 15, 2025

Top 5 Trends Shaping Custom Part Manufacturing in 2024&2025

In 2024-2025, custom parts manufacturing is undergoing a tech-driven revolution, with CNC machining, sheet metal fabrication, silicone molding, and injection molding leading the transformation of how custom manufactured parts are produced.

Jun 17, 2025

Thermoforming vs. Injection Molding: Which is Best for Your Project?

Compare thermoforming vs injection molding for custom parts—learn key differences in process, cost, materials, and applications (medical, automotive). Find the right method for your project.

Jun 12, 2025

The Future of Injection Molding Technology: From Home Appliances to Aerospace

This blog explores the key trends shaping the future of injection molding, how they’re tailored to home appliances and aerospace, and what custom parts manufacturers need to know to stay ahead.

Mar 22, 2025

Aluminum vs. Stainless Steel: Choosing the Right Material for CNC Custom Parts

Compare aluminum (6061-t6, 7075-t6 alloy) vs. stainless steel (304, 316) for CNC custom parts. Learn about machinability, corrosion resistance, cost, and uses (aerospace, medical).

Jun 17, 2025

Designing for CNC Machining: Tips for Precision and Efficiency

Learn how to optimize your designs for CNC machining to reduce costs and improve quality.

Jul 24, 2025

With the continuous innovation of society and technology, the demand for skilled CNC operators in the manufacturing industry will continue to grow.

Jul 24, 2025

CNC Guide: What is CNC Milling?

If technology is always improving, then CNC milling will never stop. In today's society, many products we use in our lives are inseparable from CNC milling.

Jul 24, 2025

CNC turning is an indispensable part of CNC machining. In this article, we will conduct an in-depth discussion to give everyone a clear understanding of CNC turning.

Oct 16, 2025

Thermoforming vs. Injection Molding: Choosing the Right Solution for Custom Plastic Projects

This guide breaks down exactly how the thermoforming & injection molding process works and how to choose the right one for your work.

Jul 24, 2025

Thermoforming Technology Explained: A Comprehensive Guide from Principles to Applications

In modern manufacturing, thermoforming stands out as a highly efficient and adaptable plastic processing technique. From transparent food containers in supermarkets to intricately designed automotive dashboards, this technology plays a pivotal role. As a parts manufacturer specializing in vacuum forming, we invite you to explore how thermoforming transforms ordinary plastic sheets into versatile, functional products.

Jul 24, 2025

This blog will delve into the details of vacuum casting, its workflow, types, materials, etc. Let you understand this special process of vacuum casting.

Jun 17, 2025

Vacuum Casting for Prototyping: Why It's a Game-Changer

Discover why vacuum casting is a game-changer for prototyping. Our guide covers the vacuum casting process, benefits of polyurethane vacuum casting, and how to choose a service for high-quality prototypes.

Jul 24, 2025

In this blog, we will explore the complexity of injection molding, its principles, processes, materials, applications, and more. Click to see more.

Jun 17, 2025

Injection Molding for High-Volume Production: What You Need to Know

Learn how to optimize high volume injection molding—from simulation and tolerances to surface finish and system design. Partner with the best injection molding company for scalable success.

Jul 24, 2025

With the continuous development of social progress, in the modern sheet metal processing industry, metal stamping technology can be said to be rich and colorful.

Jul 24, 2025

In sheet metal manufacturing, metal can be cut. In addition to several common cutting processes, there is also a more common and special cutting process - the sheet metal shearing process.

Jul 24, 2025

In the field of manufacturing and processing, sheet metal cutting plays a vital role. It can be said that the sheet metal cutting step is the most basic operation in manufacturing sheet metal parts.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us