Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

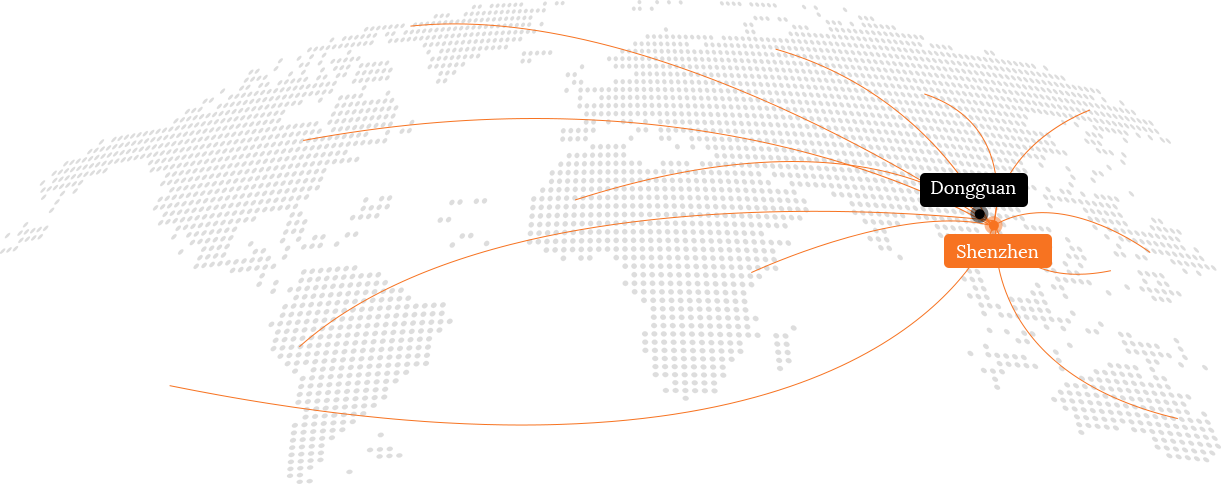

80+

Countries and regions

170000+

Registered buyers worldwide

10million

Cumulative purchases exceed

240000+

Engineering drawings

WHAT WE OFFER

Our Manufacturing Solutions

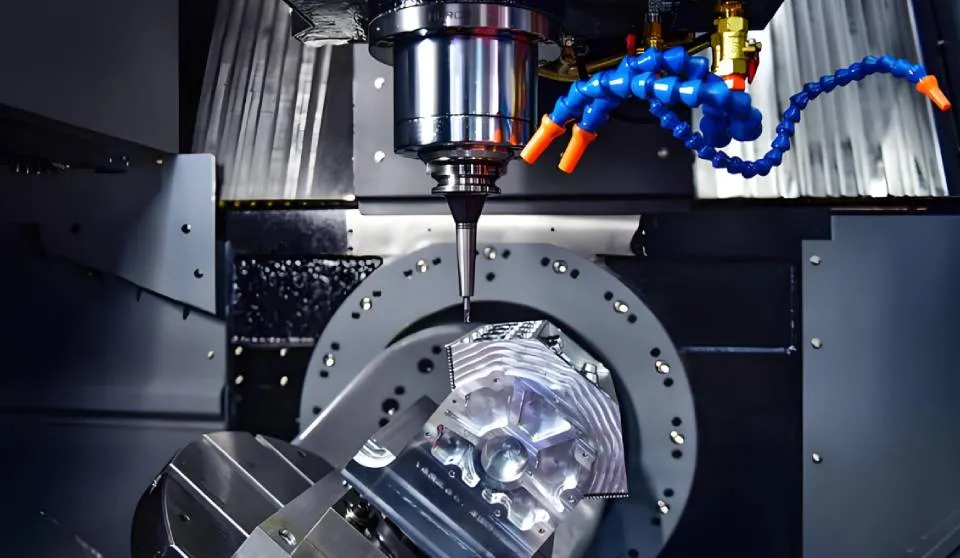

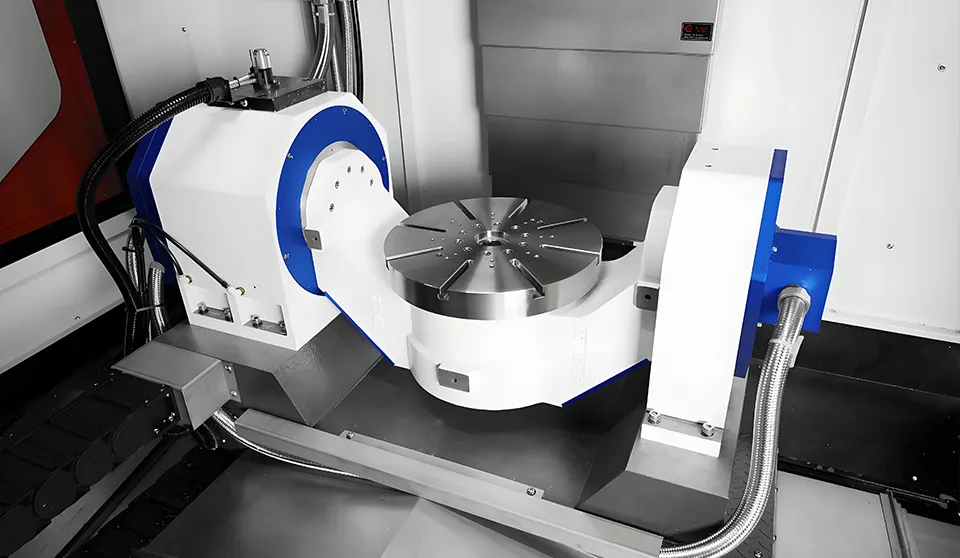

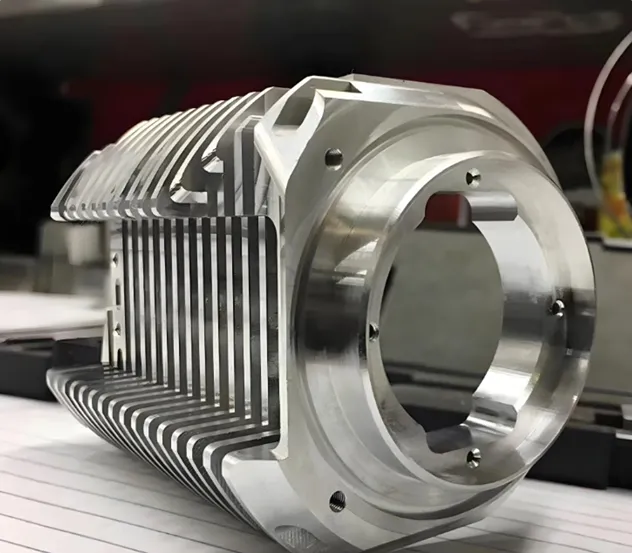

CNC milling tolerance: ±0.02mm-±0.005mm

CNC turning tolerance as low as ±0.0003 inches (±0.010 mm)

CNC machines: 15cnc lathes + 35 (3&4&5) milling machines

Maximum part processing size:

3200mm*2300mm*1000mm

Processable materials: common metals & plastics other than metal tungsten alloys

Large-scale machining of parts in just a few days

Tolerances as low as ±0.0003 inches (±0.010 mm)

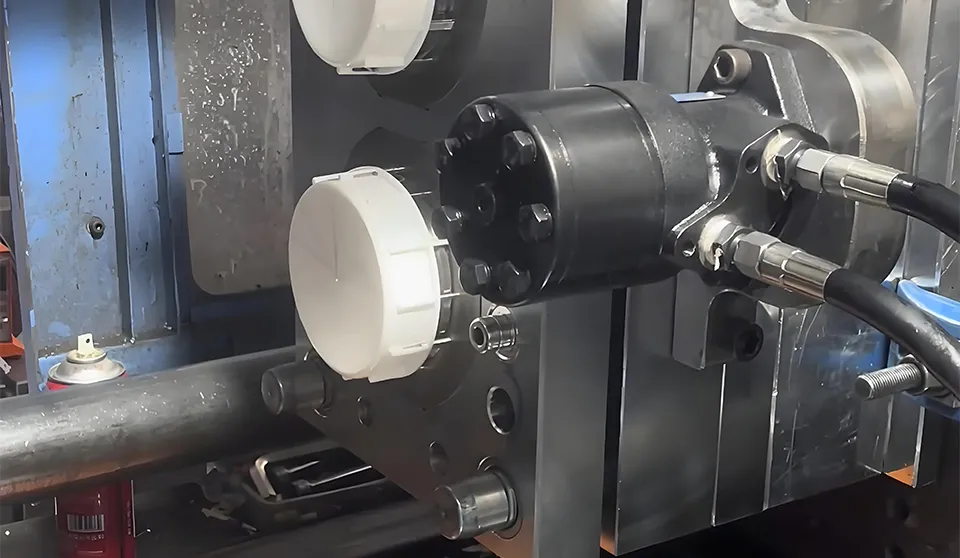

CNC (engraving and milling machine) working stroke:

500*600*210MM - 1500*2200*500MM

Accuracy: ±0.02 - ±0.05mm

Air compressor working stroke:

maximum 22KW

Maximum processing aperture 32mm

Cutting stroke: 1.5KW - 6KW

Processing materials: steel plate

materials below 6MM

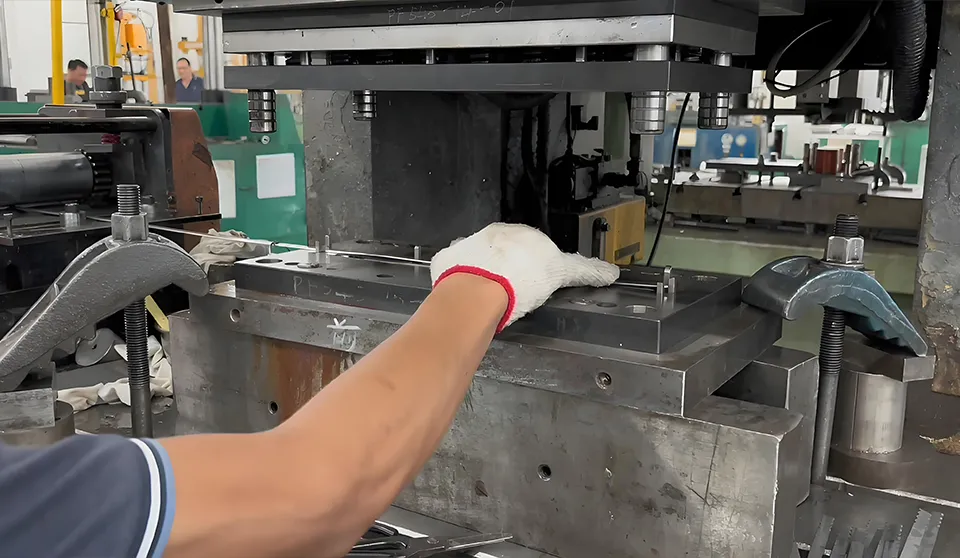

Provide free assembly service

Discover and help you solve problems such as parts and accessories conflicts at the source of production.

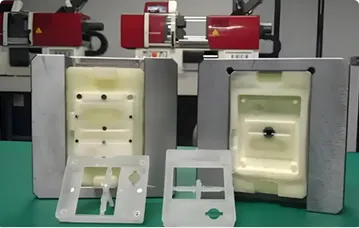

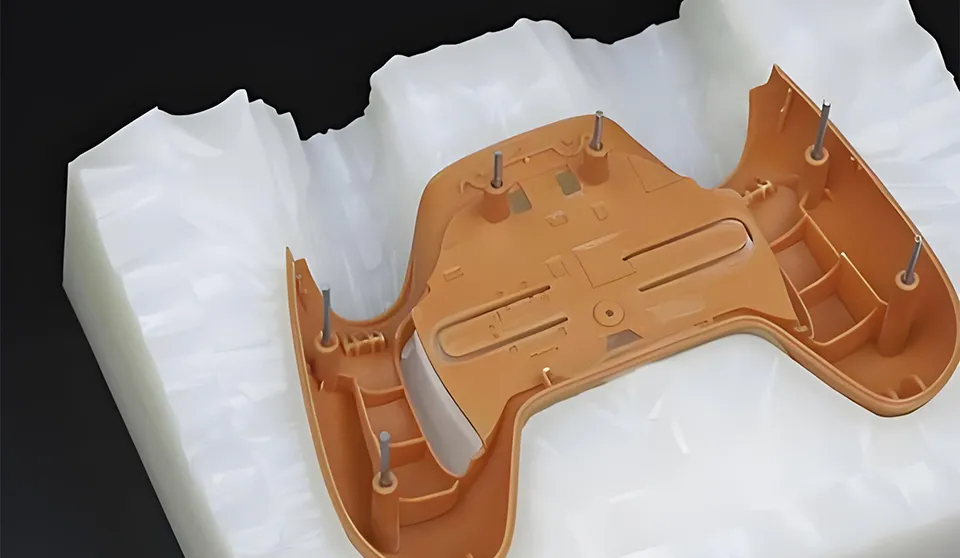

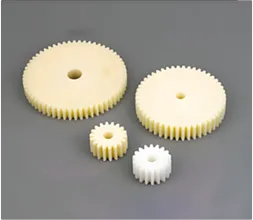

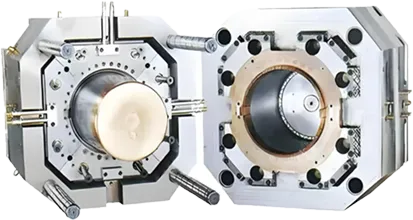

Manufacturing tolerance: ±0.004 to 0.012 Inch (±0.10 -±0.30mm)

Processing materials: more than 100 kinds,

General plastics (such as PE)

Engineering plastics (such as PA)

Special plastics (such as PTFE)

Injection molding machines: 14 units

Provide general plastics (such as PE), engineering plastics (such as PA), special plastics (PTFE)

Tolerances as low as ±0.004 to 0.012 inches (±0.10-±0.30mm)

SINCE 2014

RT is committed to becoming an excellent global manufacturing solution provider. With parts manufacturing as the core, driven by innovative processing technology and high-quality services, we meet customers' diverse needs for customized parts. We control the parts manufacturing process layer by layer to ensure that the parts quality of all your manufacturing projects is consistent.

LEADER IN PRECISION MOLD MANUFACTURING

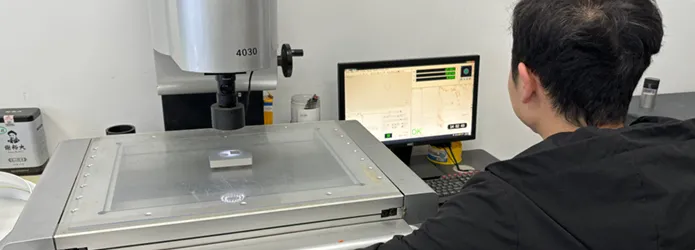

RT Manufacture Product Manufacturing Quality Control

Every step we take is to ensure that every customer who trusts us can use the parts produced by RT with peace of mind.

On the one hand, we have established a comprehensive and strict quality assurance system, and implement strict monitoring and management at every stage from raw material procurement to finished product delivery.

On the other hand, we have established an independent and professional quality inspection department, equipped with advanced testing equipment and skilled quality inspection personnel, to conduct comprehensive and multi-level inspections of products.

Not only that but In the process of product design and manufacturing, we strictly follow the prescribed tolerance requirements. The design department accurately determines the reasonable tolerance range based on the functional requirements and usage environment of the product, and clearly marks it on the design drawings.

Our manufacturing goal is to provide the best service quality to the industries that need manufactured parts. Through years of hard work and persistence, we have obtained ISO 9001:2015 and IATF16949:2016 certifications, as well as ISO 13485:2016 certifications. These certifications prove that our quality management system throughout the supply chain is completely reliable.

To ensure all parts look and perform to your specifications, we perform the highest level of inspection on all parts using calibration equipment and visual quality in a light-controlled environment.

WHAT WE OFFER

Our Core Manufacturing Processes

At the RT manufacturing platform, we have a variety of parts manufacturing technologies, including but not limited to the following.

VARIOUS MATERIALS AVAILABLE

A Wide Range Of Manufacturing Materials

At RT, we offer you a wide range of manufacturing materials, whether special metals or composite plastic materials, and we can support your manufacturing projects. The range of materials RT provides covers the following common materials but is not limited to those listed below

OUR ADVANTAGE

Why Choose Us

In the highly competitive field of processing and manufacturing, choosing the right partner is crucial to a company's success. With a series of outstanding advantages, we have become the trusted choice of many buyers.

Excellent Processing Capability

Advanced equipment and exquisite craftsmanship

Wide range of material adaptability

Efficient and flexible production

Seamless switching from single-piece small batch customization to large-scale production

Quickly respond to your diverse order needs

Shorten production cycle, emergency orders are 10% shorter than peers in delivery time

Professional Project Management

Senior project manager team:

From order placement to production delivery, the whole process is carried out in an orderly manner

You can view project dynamics anytime and anywhere

Strict quality control system

Timely After-sales Service

Transportation tracking

7×24 hours customer service hotline

All-round technical support

Product quality greetings

Problem-solving

Continuous follow-up and satisfaction return visits

Choosing us means choosing an efficient, economical and reliable processing technology service partner. We will help your company achieve greater success in the market with excellent quality, efficient delivery, and considerate service.

ACCESSORIES SUPPLY

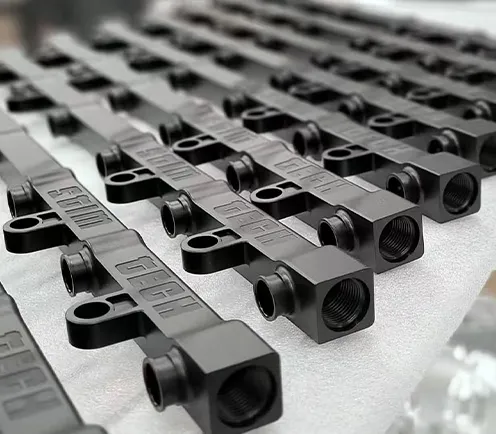

Custom Part Post-processing Show

At the RT platform, we meet almost any order requirements, including complex and beautiful custom parts,

materials, and a range of post-processing options. You can find the parts processing effect you want here

OUR INDUSTRY

What kind of Fields WE are working in

We produce millions of parts for a variety of industries around the world. Maybe something around you has a part that we make.

Automobile

Medical Equipment

Aerospace

Industrial Equipment

Energy Industry

Communications

Robotics

Lighting

Automobile

Automobile parts are highly precise and need to be wear-resistant and pressure-resistant. Our parts manufacturing services are suitable for a variety of models, ensuring safe and stable driving, and helping to improve the efficient power transmission and controllability of automobiles.

Medical Equipment

Our medical parts are made of safe and compliant materials with strict precision requirements. They are related to diagnostic accuracy and treatment effects, safeguarding life and health, and are extremely reliable.

Aerospace

Our aerospace parts are lightweight and strong and can withstand extreme environments. They have a critical impact on aircraft performance, ensuring safe and efficient flight, and helping to explore deep space.

Industrial Equipment

Our industrial parts are highly adaptable, durable, and easy to maintain. They can operate stably under complex working conditions, improve industrial production efficiency and quality, and support the continuous operation of production lines.

Energy Industry

RT's energy parts are resistant to high temperatures and high pressures and have efficient conductivity. They play a key role in energy production and conversion, ensuring a stable energy supply, and promoting the development of the energy industry.

Communications

RT's communication parts have accurate signal transmission, miniaturization, and integration. They meet the needs of high-speed communications, ensure smooth information transmission, and lay a solid foundation for the global communication network.

Robotics

RT's robot parts are flexible, precise, and well-adaptable. They give robots diverse movements and intelligent perceptions, allowing them to work efficiently in multiple fields and promote the automation process.

Lighting

RT's lighting parts have excellent optical performance and good heat dissipation. They achieve comfortable lighting effects, are energy-saving, and have a long lifespan, creating a suitable lighting environment for various places.

FEEDBACK

Why Our Clients Trust Us?

Put Your Parts Into Production Today

Cooperation Process

01

Sign NDA

02

Quotation & Suggestions

03

Agreement & Quotation Adoption

04

Order Confirmation & Deposit

05

Production & Quality Control

06

Fianl Picture & Video Confirmation

07

Final Payment & Delivery

08

After-sales Support

Our Project Manufacturing Cases

CNC Machining Case

Sheet Metal Case

Injection Molding Case

Vacuum Casting Case

CNC Machining Case

DJI Drone Motor Mounts

Learn about our exciting story of drone manufacturing with DJI Innovations. Our large-scale aerospace precision manufacturing can achieve monthly batch production of up to tens of thousands of units.

Sheet Metal Case

Schneider Electric Server Racks

Leverage our sheet metal fabrication technology to produce batches of critical sheet metal parts for a data armor giant, using 22% less material than the industry average.

Injection Molding Case

Medtronic Insulin Pump Housings

It took us just over a month to produce exquisite injection-molded crafts, and we have produced more than one million pieces so far.

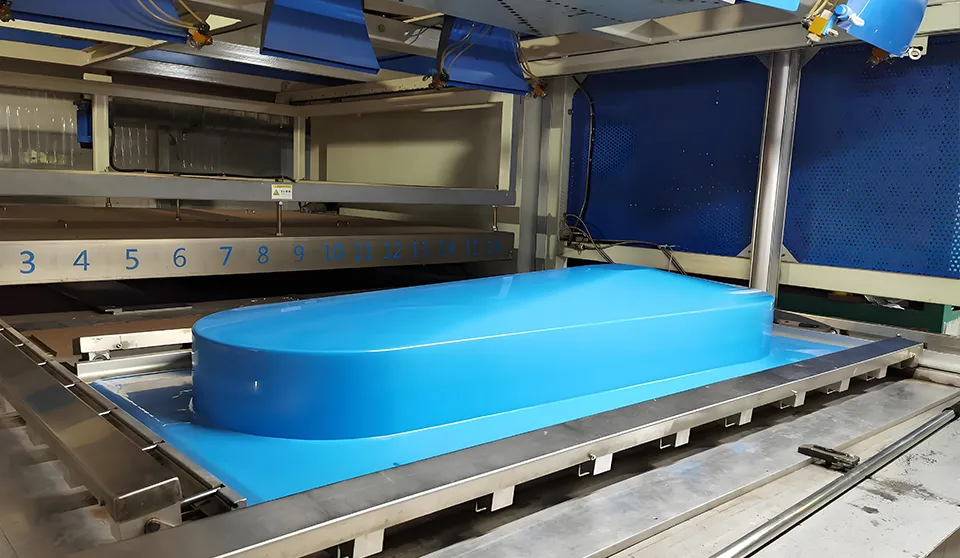

Vacuum Casting Case

Porsche Headlight Prototypes

We used silicone molding technology to achieve a smooth Fresnel lens that cannot be achieved through CNC processing. The polished silicone parts achieved a 92% light transmittance, thus fooling Porsche's spectrometer.

NEWS AND BLOGS

Get to Know Our Latest News

Blogs

News

Case Studies

Guidelines

Materials

Design Guides

CNC Machining

Thermoforming

Vacuum Casting

Injection Molding

Sheet Metal Fabrication

Oct 15, 2025

What is Teflon surface treatment?

In this article, we'll break down each step of the Teflon process, detail which materials can (and can't) be Teflon-coated, and explain why this treatment technique changes the game for part surfaces.

Jul 24, 2025

That unassuming "right angle" marked on your issued drawing could secretly plant the seeds of product failure, cost explosions, or even customer claims.

Apr 20, 2025

How Does CNC Machining Drive Innovation in Automotive Parts Manufacturing?

CNC machining, with its high precision and efficiency, is reshaping the automotive parts manufacturing industry. This article will explore the applications of CNC milling and turning in the automotive sector and how they help manufacturers achieve lighter, more durable components.

Oct 29, 2025

Global Supply Chain Shifts: How Chinese Machining Suppliers Deliver Value and Reliability

Explore how China's machining sector combines advanced technology with supply chain resilience to provide precision parts and custom machining solutions in evolving global markets.

Oct 22, 2025

How Custom Part Manufacturing is Revolutionizing the Medical Equipment Industry

In the ever-evolving landscape of healthcare, medical equipment stands as the backbone of moder diagnosis and treatment.

Jun 12, 2025

The Key Role of Sheet Metal Processing in Home Appliance Manufacturing

This blog breaks down how sheet metal processing—and its related techniques like sheet metal manufacturing shape the appliances we use every day, and why it’s irreplaceable in appliance production.

Jun 30, 2025

CNC Machining Case: DJI Drone Motor Mounts

Learn about our exciting story of drone manufacturing with DJI Innovations. Our large-scale aerospace precision manufacturing can achieve monthly batch production of up to tens of thousands of units.

Jun 30, 2025

Sheet Metal Case: Schneider Electric Server Racks

Leverage our sheet metal fabrication technology to produce batches of critical sheet metal parts for a data armor giant, using 22% less material than the industry average.

Jun 30, 2025

Injection Molding Case: Medtronic Insulin Pump Housings

It took us just over a month to produce exquisite injection-molded crafts, and we have produced more than one million pieces so far.

Oct 29, 2025

Navigating Tariff Wars: A Strategic Guide to Sourcing Custom Machined Parts

Facing supply chain disruptions from trade conflicts? Discover how to secure reliable custom machining solutions through strategic partnerships, regional diversification, and technical collaboration. Learn about RT Manufacture's resilient approach.

Oct 15, 2025

Top 5 Trends Shaping Custom Part Manufacturing in 2024&2025

In 2024-2025, custom parts manufacturing is undergoing a tech-driven revolution, with CNC machining, sheet metal fabrication, silicone molding, and injection molding leading the transformation of how custom manufactured parts are produced.

Jun 17, 2025

Thermoforming vs. Injection Molding: Which is Best for Your Project?

Compare thermoforming vs injection molding for custom parts—learn key differences in process, cost, materials, and applications (medical, automotive). Find the right method for your project.

Jun 12, 2025

The Future of Injection Molding Technology: From Home Appliances to Aerospace

This blog explores the key trends shaping the future of injection molding, how they’re tailored to home appliances and aerospace, and what custom parts manufacturers need to know to stay ahead.

Mar 22, 2025

Aluminum vs. Stainless Steel: Choosing the Right Material for CNC Custom Parts

Compare aluminum (6061-t6, 7075-t6 alloy) vs. stainless steel (304, 316) for CNC custom parts. Learn about machinability, corrosion resistance, cost, and uses (aerospace, medical).

Jun 17, 2025

Designing for CNC Machining: Tips for Precision and Efficiency

Learn how to optimize your designs for CNC machining to reduce costs and improve quality.

Jul 24, 2025

With the continuous innovation of society and technology, the demand for skilled CNC operators in the manufacturing industry will continue to grow.

Jul 24, 2025

CNC Guide: What is CNC Milling?

If technology is always improving, then CNC milling will never stop. In today's society, many products we use in our lives are inseparable from CNC milling.

Jul 24, 2025

CNC turning is an indispensable part of CNC machining. In this article, we will conduct an in-depth discussion to give everyone a clear understanding of CNC turning.

Oct 16, 2025

Thermoforming vs. Injection Molding: Choosing the Right Solution for Custom Plastic Projects

This guide breaks down exactly how the thermoforming & injection molding process works and how to choose the right one for your work.

Jul 24, 2025

Thermoforming Technology Explained: A Comprehensive Guide from Principles to Applications

In modern manufacturing, thermoforming stands out as a highly efficient and adaptable plastic processing technique. From transparent food containers in supermarkets to intricately designed automotive dashboards, this technology plays a pivotal role. As a parts manufacturer specializing in vacuum forming, we invite you to explore how thermoforming transforms ordinary plastic sheets into versatile, functional products.

Jul 24, 2025

This blog will delve into the details of vacuum casting, its workflow, types, materials, etc. Let you understand this special process of vacuum casting.

Jun 17, 2025

Vacuum Casting for Prototyping: Why It's a Game-Changer

Discover why vacuum casting is a game-changer for prototyping. Our guide covers the vacuum casting process, benefits of polyurethane vacuum casting, and how to choose a service for high-quality prototypes.

Jul 24, 2025

In this blog, we will explore the complexity of injection molding, its principles, processes, materials, applications, and more. Click to see more.

Jun 17, 2025

Injection Molding for High-Volume Production: What You Need to Know

Learn how to optimize high volume injection molding—from simulation and tolerances to surface finish and system design. Partner with the best injection molding company for scalable success.

Jul 24, 2025

With the continuous development of social progress, in the modern sheet metal processing industry, metal stamping technology can be said to be rich and colorful.

Jul 24, 2025

In sheet metal manufacturing, metal can be cut. In addition to several common cutting processes, there is also a more common and special cutting process - the sheet metal shearing process.

Jul 24, 2025

In the field of manufacturing and processing, sheet metal cutting plays a vital role. It can be said that the sheet metal cutting step is the most basic operation in manufacturing sheet metal parts.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us