Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

Our Online Sheet Metal Fabrication Services

We offer a wide range of sheet metal fabrication options. With our extensive sheet metal manufacturing and finishing capabilities, we can produce precise, high-quality parts, whether your sheet metal project involves a single prototype or multiple components.

Custom sheet metal fabrication services are one of our four core fabrication technologies. We provide different personalized needs for each customer. The following items are custom services we currently offer:

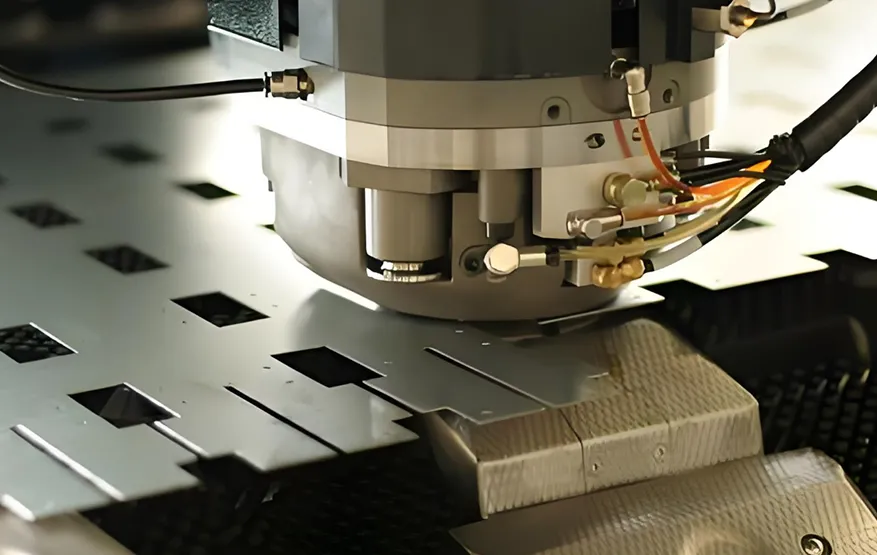

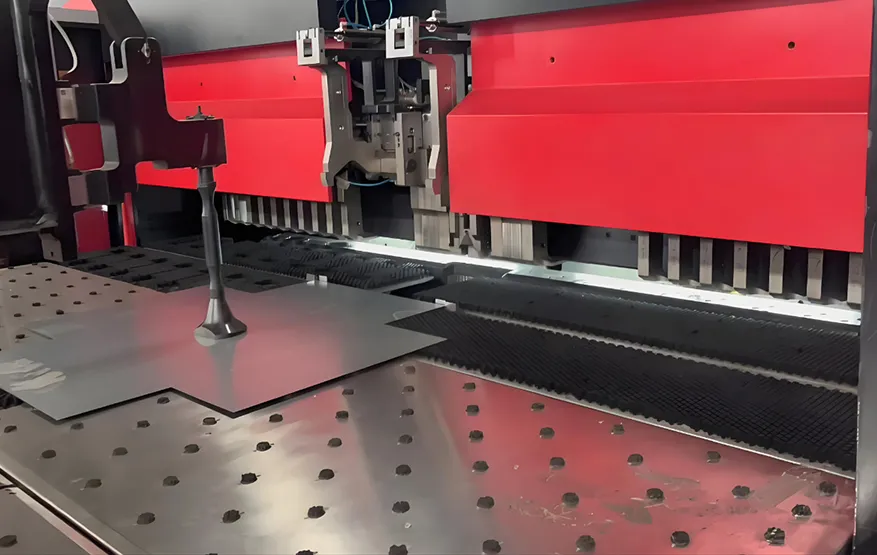

Sheet Metal Cutting

Sheet metal cutting is the process of shaping thin metal sheets (typically less than 6mm thick) into the desired shape. At RT, we use a variety of cutting techniques to cut a wide range of complex and diverse sheet metal component shapes.

Sheet Metal Shearing

Sheet metal shearing is the most basic processing technology in sheet metal processing. Shearing machines are used to shear metal materials, and various operations such as twisting, grooving, and grinding can be performed. The shearing processes include mechanical shearing, laser shearing, plasma shearing, and water jet shearing.

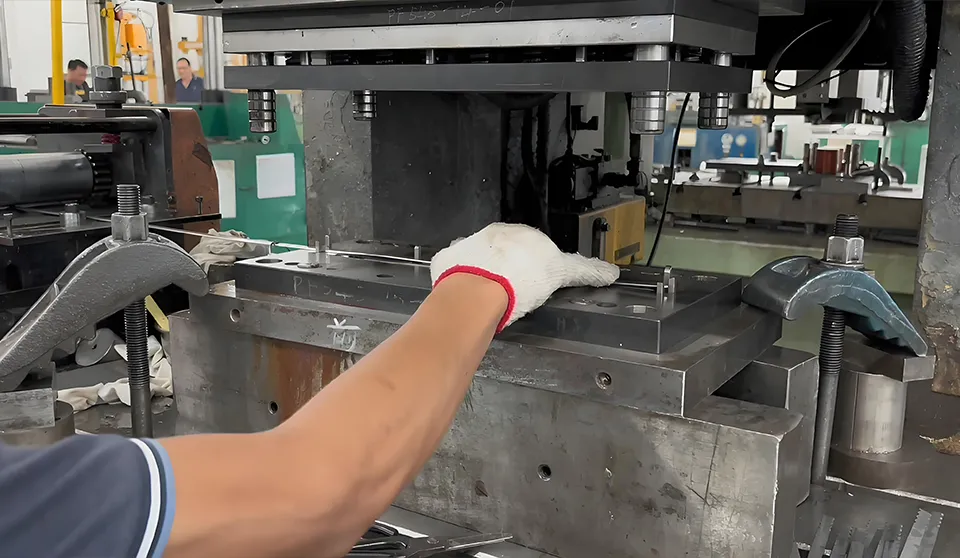

Sheet Metal Stamping

Sheet metal stamping is a forming method that uses a press and a die to apply external force to a metal sheet to cause it to undergo plastic deformation or separation, thereby obtaining a workpiece (stamping part) of the desired shape and size. Sheet metal stamping is widely used in sheet metal manufacturing, especially in the fields of automobiles, electrical appliances, aerospace, and machinery manufacturing.

Sheet Metal Forming

Sheet metal forming technology is a comprehensive cold processing technology for thin metal sheets (usually less than 6mm). Metal sheets are processed into sheet metal parts or components with specific shapes and sizes through stamping, bending, stretching, and other processes. In sheet metal processing, sheet metal forming is one of the most widely used manufacturing technologies.

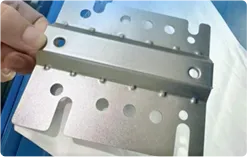

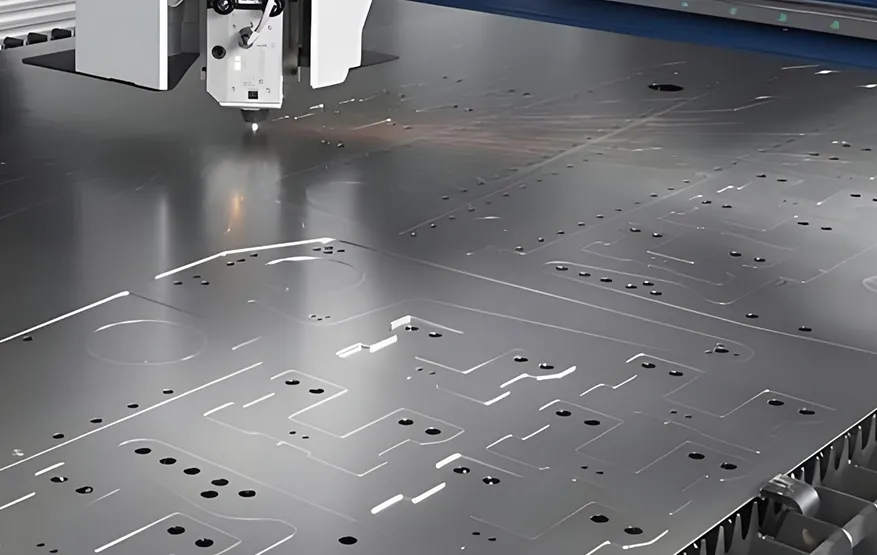

Sheet Metal Hole Fabrication

Sheet metal punching refers to a processing method that uses punching equipment such as punching machines to punch out pre-designed holes through a stamping die. It is usually used to make various sheet metal parts. Sheet metal hole processing is widely used in the production of various sheet metal products, such as the electronic and electrical industry, communications industry, automotive industry, medical equipment, and other fields.

Our Sheet Metal Tolerances

We pursue higher quality sheet metal tolerances than other sheet metal manufacturers. While the maximum part size and thickness may vary depending on the sheet metal used, our accuracy capabilities remain the same for all parts.

For sheet metal parts with linear tolerances, we follow the ISO 2768-mk ISO 2768 tolerance standard. The maximum dimensional accuracy we can achieve is +/—0.2 mm (+/—0.008 in). Without a drawing, the maximum tolerance we can achieve is +/—0.3 mm (+/—0.012 in).

| Metric | US | |

| Minimum Lead Time | 5 days | 5 days |

| Maximum Laser Power | 5 kW | 5 kW |

| Dimensional Accuracy | ±0.2 mm | ± 0.005 |

| Laser Kerf | 0-0.15 mm | 0-0.008 |

| Material Thickness | 0.1-26 mm | 0.004-1.02 |

| Maximum Part Size | 3500x 1800× 26 mm | 138 x 71 x 1.02 Inches |

| Minimum Part Size | 10x10x 0.3 mm | 0.39 × 0.39 x 0.012 inches |

| Minimum Feature Size | 1x Material Thickness (minimum 1 mm) | 1x Material Thickness (0.04 inches minimum) |

| Part Complexity | 1-100,0000 | 1-100,0000 |

| Part Complexity Free | Guaranteed Tolerances | Guaranteed Tolerances |

Our Sheet Metal Material Options

Metal

Aluminum

Steel

Cold Rolled Steel (SPCC)

Hot Rolled Steel (SHCC)

Brass

Bronze

Copper

Beryllium Copper

Stainless Steel

Nickel Alloy

Aluminum

Aluminum is a lightweight, corrosion-resistant metal material that contains a variety of excellent performance combinations. It is widely used in various fields due to its different structural characteristics.

Common aluminum alloys:

1050, 2024, 5052, 6063, 6061-T6, 6061-T651, 7075-T6, 7050, MIC6

Finish options:

Passivation, anodizing type II, III, electrophoresis, sandblasting, nickel plating, powder coating, drum polishing, silk screen, oil spraying.

Steel

RT provides a variety of customized steel solutions for each customer to meet the needs of various scenarios. Each steel can show its excellent characteristics according to different application areas.

Common alloys:

4140, 4130,4340, A514

Carbon steel types:

1018 low carbon, 1045 carbon, galvanized low carbon, etc.

Finish options:

Electrolytic polishing, sandblasting, nickel plating, silk screen, powder coating, drum polishing, galvanizing, black oxide

Cold Rolled Steel (SPCC)

Cold-rolled steel is a kind of steel with high strength, a hard structure, and a bright surface. Usually, the material thickness is ≤3.2mm. It is widely used because of its low cost and easy-forming characteristics.

Common alloy models:

Q195, Q215A

Finish options:

Passivation, Galvanized, electrophoresis, sandblasting, nickel plating, powder coating, drum polishing, silkscreen, oil spraying.

Hot Rolled Steel (SHCC)

Hot rolled steel is a steel plate produced by a high temperature rolling process. Hot rolled steel has a lower hardness but higher strength, and the material thickness is usually between 1.2mm and 25mm.

Common grades:

Q235, Q345, SS400, SPHC, S235JR, 20g, 16Mng, 15CrMog, 12Cr1MoV

Surface treatment:

Sandblasting, powder spraying, drum polishing, silk screen printing, oil spraying

Brass

Brass is an alloy mainly composed of copper and zinc, with a golden and shiny surface. Brass has high strength and strong wear resistance and is often used to manufacture mechanical parts and corrosion-resistant industrial products.

Common alloy models:

H59, H62, H63, H65, H68, H70, H75, H80, H85, H96, H90, T1, T2

Surface treatment:

Laser carving, galvanizing, sandblasting, nickel plating, powder spraying, drum polishing, silk screen printing, and oil spraying.

Bronze

Bronze is a machine tool sheet metal material composed of copper, tin, and other components, which has corrosion resistance, high hardness, and strength. Bronze is widely used in the manufacture of digital game machine tool sheet metal parts, brake systems, and automotive parts.

Common alloy models:

QSn6.5-0.1, QSn4-3, ZCuSn6Zn6Pb3, QAl10-3-1.5, ZCuAl10Fe3, Pb15Sn7, C19150, C31400, C31600, Hsn62-1, Qsn4-3, Qsn5-5-5

Surface treatment:

Galvanizing, laser engraving, sandblasting, nickel plating, powder coating, drum polishing, silk screen printing, oil spraying.

Copper

Copper is industrial pure copper, with high oxygen content, purity up to 99.9%, and rose red surface. Copper has relatively low strength and poor cutting performance, but it has excellent electrical conductivity and good corrosion resistance. Usually, the thickness of copper sheet material is between 0.5mm-3mm.

Common alloy models:

C11000, C10200, C12200

Surface treatment:

Galvanizing, sandblasting, nickel plating, powder spraying, drum polishing, laser engraving, silk screen printing, oil spraying.

Beryllium Copper

Beryllium copper is a copper alloy with beryllium as the main alloying element. It has the characteristics of high hardness, low thermal expansion coefficient, and easy processing. Beryllium copper is often used as a material for making precision sheet metal prototypes, especially for applications that have high requirements for precision, conductivity, and heat resistance.

Common alloy models:

C17200, C17500, C17510, QBe2, QBe1.9, QBe2.5

Surface treatment:

Galvanizing, sandblasting, nickel plating, powder coating, drum polishing, laser engraving, silk screen printing, oil spraying.

Stainless Steel

Stainless steel is a high alloy steel that can resist corrosion in air or chemical corrosive media. In sheet metal processing, stainless steel is the most widely used steel. Generally speaking, the hardness of stainless steel is higher than that of aluminum alloy.

Common alloy models:

303, 304, 316, 321, 347, 904L, 409, 430, 410, 420, 2205, 17-4PH

Surface treatment:

Passivation, galvanizing, electrophoresis, sandblasting, nickel plating, powder spraying, polishing, silk screen printing, oil spraying, wire drawing, laser engraving

Nickel Alloy

Nickel alloy is composed of nickel as the matrix and other elements. It has excellent heat resistance, corrosion resistance, and mechanical properties and is widely used in electronics, the chemical industry, machinery, medical treatment, energy development, navigation, aerospace, and other industries.

Common grades

N2、N4、N6、UNS N04400、UNS N06600、UNS N06625、Inconel 600

Surface treatment

Polishing, electroplating, powder coating, passivation, anodizing, thermal spraying, chrome plating, galvanizing, silk screen printing, laser engraving, etc.

Put Your Parts Into Production Today

What We Do Sheet Metal Finishing

As a mature sheet metal processing manufacturer, in addition to manufacturing sheet metal parts, we also provide a variety of sheet metal surface treatment options. The following are several common sheet metal post-processing. If you want more, please contact us by phone or email to see what post-processing we can do for you.

Sheet Metal Surface Treatment We Provide

Sheet metal surface treatment is carried out after processing is completed. The surface treatment of sheet metal can change its appearance to a certain extent, affecting its surface roughness, hardness, and other characteristics, achieving the purpose of beauty and durability.

This is our standard surface treatment. When the parts are delivered, the sharp edges are ground to remove burrs, no other additional processing is done.

Glass beads are evenly attached to the sheet metal through a high-compressed air flow to form a granular texture. It plays a role in cleaning parts, improving surface roughness, and improving mechanical properties.

The surface of the sheet metal is ground in a certain direction with a specific sandpaper model to produce linear textures and effects.

Sandblasting + Anodizing Type II

After sandblasting, the parts are then subjected to ordinary anodizing (Type II). The service life, corrosion resistance, and aesthetics of the sandblasted sheet metal after anodizing will be significantly improved.

After the brushed process, the metal parts are immersed in an anodizing tank (Type II). While improving the corrosion resistance of the sheet metal, a certain aesthetic effect is also achieved.

Anodizing Type III (Hard Coating)

After the sheet metal is manufactured, it is placed in an anodizing (Type III) tank. To improve the wear resistance and corrosion resistance of the parts. Hard coating has better corrosion resistance than anodizing (Type II).

After the parts are manufactured, the metal surface is sprayed with paint. The spraying process can make the metal sheet metal corrosion-resistant while taking into account a certain aesthetic surface.

After the parts are manufactured, the required powder coating is sprayed to give the sheet metal a certain corrosion resistance. Colors are available.

Black oxide is also called blackening treatment. A thin layer of black oxide film will form on the surface of the parts after blackening. Blackening treatment can not only improve the corrosion resistance of the surface of the parts but also give the parts a beautiful appearance.

After the parts are manufactured, the passivation treatment is carried out to form a protective film on the surface of the metal parts, so as to achieve the ideal effect of maintaining its conductive properties while extending the service life of the metal parts.

The silk screen printing process is mainly used to mark information such as component value, part number, and polarity, as well as version, manufacturer, and other information. This information helps users identify and assemble components during assembly, and also plays an important role in maintenance and debugging.

Why Choose Our Sheet Metal Processing Service?

In the field of injection molding, RT provides customers with high-quality products and services with its excellent quality management system. Choosing RT MANUFACTURE means choosing high quality and high reliability.

01.

Strict selection of raw materials

We have established long-term cooperative relations with high-quality raw material suppliers in the industry. International standards strictly inspect all incoming materials to prevent unqualified products from entering the processing link and ensure product quality from the source.

02.

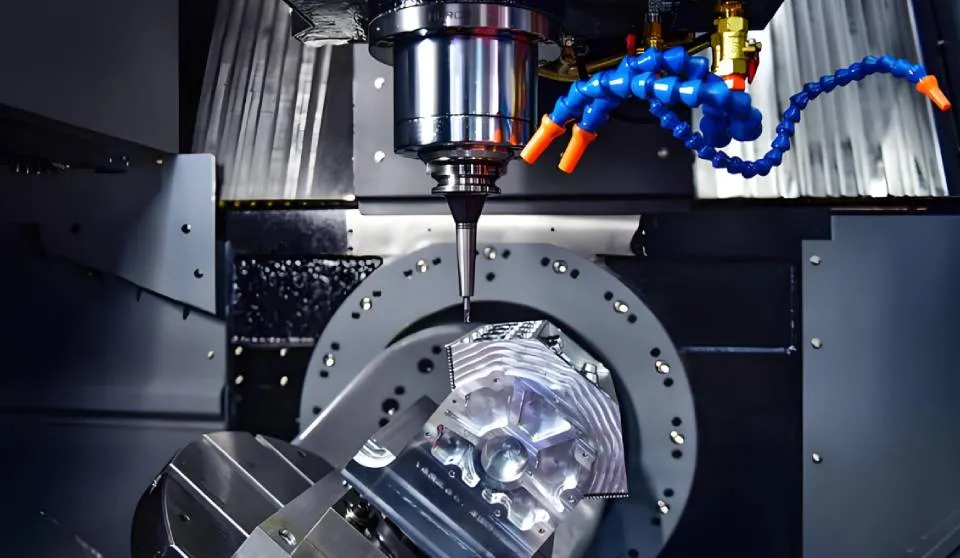

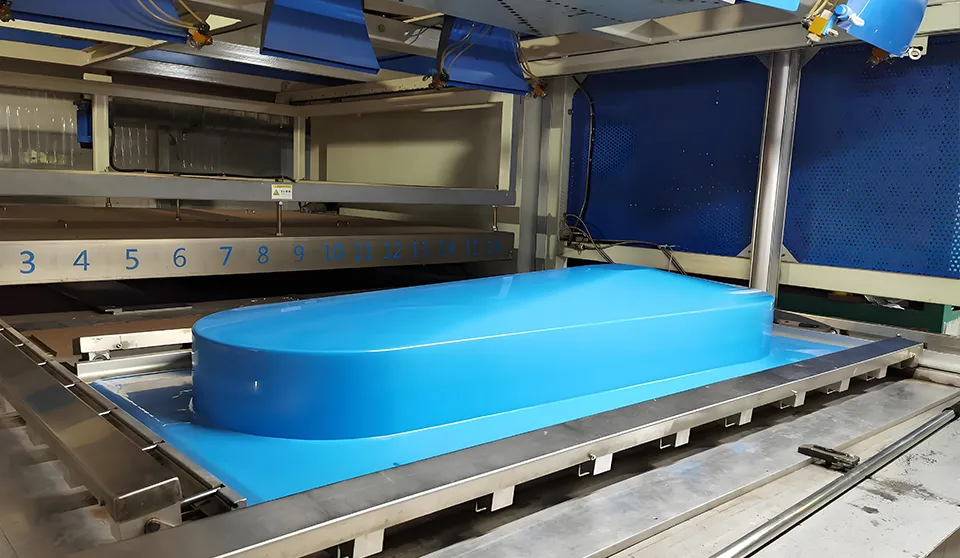

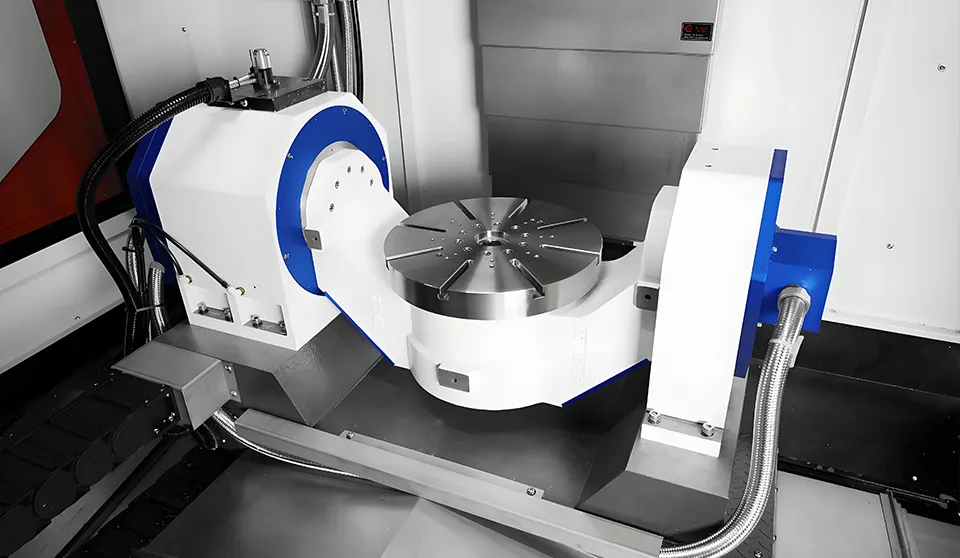

Advanced processing technology

Introducing international cutting-edge sheet metal processing equipment and technology, the processing process follows high-precision standard operating procedures to ensure that the part size accuracy reaches ±0.1mm and the surface flatness error is controlled within a very small range.

03.

Strict quality inspection

Build a multi-link, all-round inspection system, from real-time monitoring during the processing process to comprehensive sampling of finished products, with the help of professional inspection equipment, to ensure that the quality of each part meets high standards.

04.

Personnel management

All members of the quality management team have more than 10 years of industry experience. They regularly organize professional skills training and assessments to ensure that employees are proficient in advanced quality management concepts and methods.

05.

Quality traceability system

Establish a complete quality traceability system. From raw material procurement to finished product delivery, information at each link is recorded in detail. Once a quality problem occurs, the cause can be quickly, accurately located, and solved.

06.

Continuous quality improvement

Actively collect customer feedback and internal quality data, hold quality analysis meetings regularly, continuously optimize processing technology and quality management processes, and pursue excellent quality.

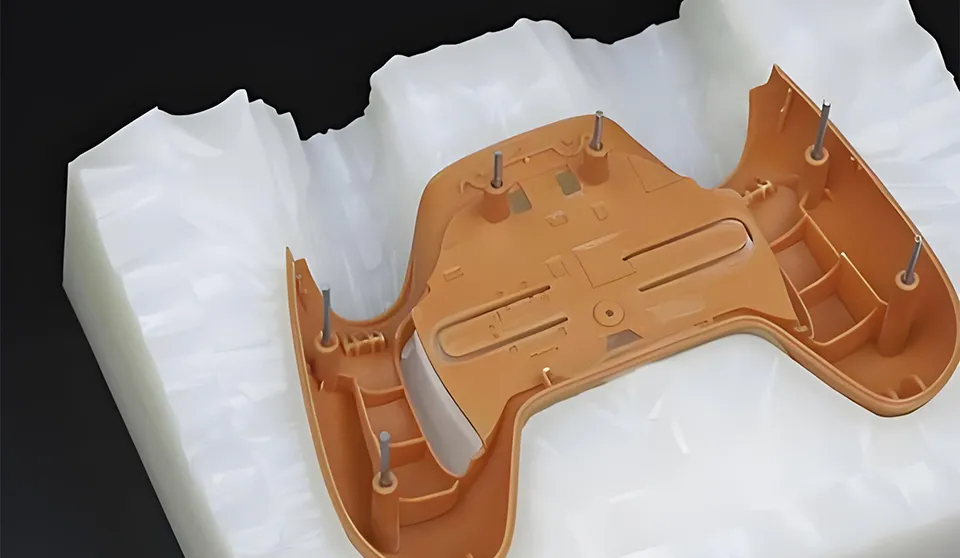

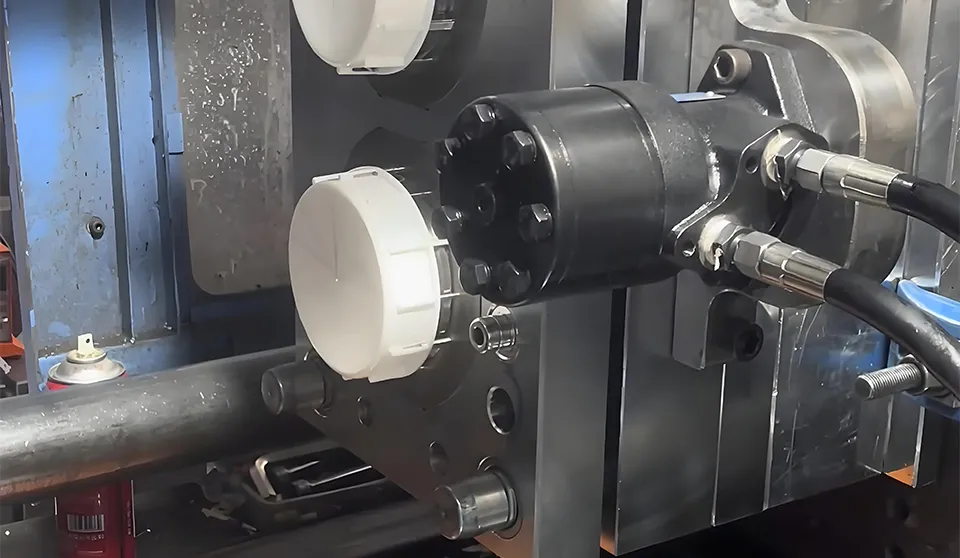

RT Sheet Metal Fabrication Shop

We can manufacture custom sheet metal parts for you through our sheet metal fabrication equipment and mature sheet metal fabrication processes. Whether you need general sheet metal prototype fabrication, stainless steel fabrication, or precision sheet metal fabrication, our sheet metal fabrication shop can solve your production problems.

Sheet Metal Finishing Application Areas

There are many application scenarios for CNC machining. The following are the most common ones in our lives

AUTOMOTIVE

MEDICAl EQUIPMENT

AEROSPACE

MACHINERY EQUIPMENT

ENERGY INDUSTRY

COMMUNICATIONS

ROBOTICS

HOME-APPLIANCE

AUTOMOTIVE

Sheet metal processing helps to improve the speed of automobile assembly and the accuracy of parts, thereby reducing manufacturing costs and improving product quality. Sheet metal manufacturing has many applications in the automotive field. For example, car doors, engine hoods, trunk lids, and other parts cannot be separated from sheet metal processing.

MEDICAl EQUIPMENT

Sheet metal processing is also widely used in the medical field. For example, the shells and internal structures of equipment such as operating tables, shadowless lamps, and anesthesia machines are often made of medical-grade stainless steel sheet metal to ensure durability, corrosion resistance, and easy equipment cleaning.

AEROSPACE

In aerospace, sheet metal forming technology plays an important role in manufacturing aircraft structural parts, mainly used to manufacture aircraft fuselages, wings, doors, and other parts. Through stamping, bending, drawing, and other processes, lightweight design can be achieved and the aircraft's overall performance can be improved.

MACHINERY EQUIPMENT

Sheet metal processing plays an important role in the field of industrial equipment. The shells, brackets, and internal structural parts of many mechanical equipment are made using sheet metal processing technology. These parts need to have good mechanical properties during use and meet the requirements of protection and aesthetics. Sheet metal processing can effectively meet these needs and ensure that mechanical equipment works normally in various harsh environments.

ENERGY INDUSTRY

The application of sheet metal fabrication technology in the energy field is also very popular. For example, it can improve the production efficiency and product quality of solar panels, reduce manufacturing costs, and promote the development of the solar energy industry.

COMMUNICATIONS

Communication is one of the important application fields of sheet metal processing. Sheet metal manufacturing technology is mainly used to manufacture the outer shell and internal structure of various wireless devices to provide necessary support and protection.

ROBOTICS

In the field of intelligent applications, sheet metal technology shows its extraordinary side. For example, the electronic components inside the robot require a good heat dissipation system. Sheet metal processing can manufacture heat sinks, heat dissipation plates, and other components, and ensure heat dissipation effect and structural stability through precise stamping and welding processes.

Sheet Metal Parts Manufacturing By RT

The sheet metal parts we professionally manufacture are made of high-quality metal plates and carefully crafted through advanced stamping, cutting, bending, and other processes. They have high precision, high strength, and fine surface treatment. They are widely used in electronics, machinery, automobiles, and other industries. They can perfectly meet various complex needs and provide reliable sheet metal solutions.

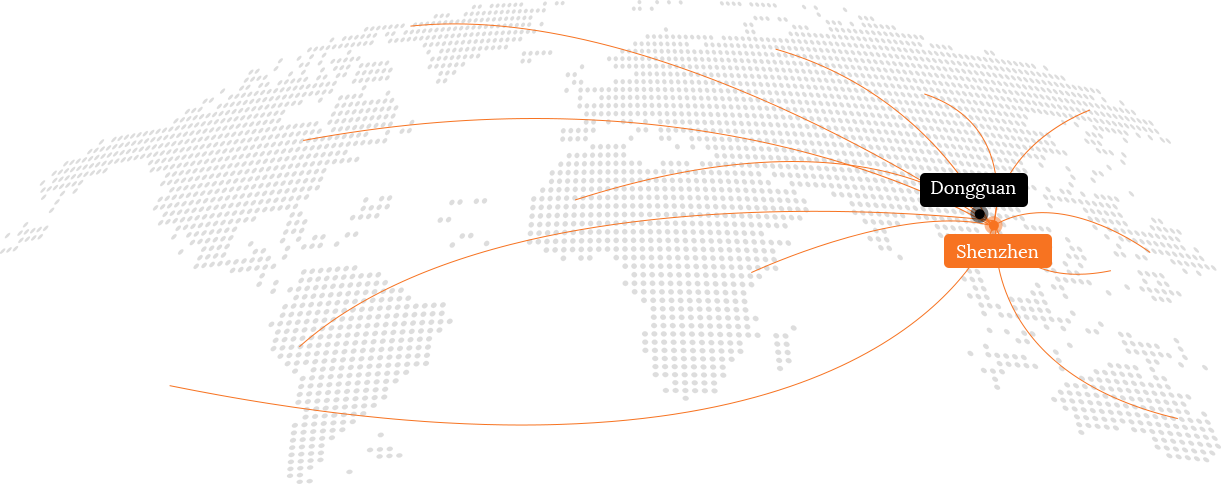

Trusted Sheet Metal Manufacturing: Voices from Satisfied Global Customers

At RT MANUFACTURE, we take pride in our sheet metal manufacturing services. Here is what some of our international clients have to say about their experience working with us.

Frequently Asked Questions About Sheet Metal Fabrication Services

What Size Sheet Metal Parts Can You Fabricate?

We are not limited by part specifications. We can meet your project needs no matter how large the sheet metal parts are as long as you need them.

What Is The Standard Time For Your Sheet Metal Fabrication Project?

The specific sheet metal fabrication project time is usually determined by the complexity, thickness, and quantity of the metal parts. Under normal circumstances, our sheet metal fabrication turnaround time starts from 5 days.

Do You Accept Customer-supplied Sheet Metal Fabrication Options?

Yes, you can provide us with your processing materials if you wish. We have this customer-supplied option.

Are These The Only Sheet Metal Fabrication Materials You Have?

No, we can provide a lot of sheet metal materials, these are just some of them. If you want more, please contact us.

Do You Have A Manufacturing Certificate?

Yes, we are ISO 9001:2015 and ISO 13485 certified. We are a first-class sheet metal fabrication supplier in terms of production process and quality control.

Sheet Metal Fabrication Resources

Blogs

News

Case Studies

Guidelines

Materials

Design Guides

CNC Machining

Thermoforming

Vacuum Casting

Injection Molding

Sheet Metal Fabrication

Oct 15, 2025

What is Teflon surface treatment?

In this article, we'll break down each step of the Teflon process, detail which materials can (and can't) be Teflon-coated, and explain why this treatment technique changes the game for part surfaces.

Jul 24, 2025

That unassuming "right angle" marked on your issued drawing could secretly plant the seeds of product failure, cost explosions, or even customer claims.

Apr 20, 2025

How Does CNC Machining Drive Innovation in Automotive Parts Manufacturing?

CNC machining, with its high precision and efficiency, is reshaping the automotive parts manufacturing industry. This article will explore the applications of CNC milling and turning in the automotive sector and how they help manufacturers achieve lighter, more durable components.

Oct 29, 2025

Global Supply Chain Shifts: How Chinese Machining Suppliers Deliver Value and Reliability

Explore how China's machining sector combines advanced technology with supply chain resilience to provide precision parts and custom machining solutions in evolving global markets.

Oct 22, 2025

How Custom Part Manufacturing is Revolutionizing the Medical Equipment Industry

In the ever-evolving landscape of healthcare, medical equipment stands as the backbone of moder diagnosis and treatment.

Jun 12, 2025

The Key Role of Sheet Metal Processing in Home Appliance Manufacturing

This blog breaks down how sheet metal processing—and its related techniques like sheet metal manufacturing shape the appliances we use every day, and why it’s irreplaceable in appliance production.

Jun 30, 2025

CNC Machining Case: DJI Drone Motor Mounts

Learn about our exciting story of drone manufacturing with DJI Innovations. Our large-scale aerospace precision manufacturing can achieve monthly batch production of up to tens of thousands of units.

Jun 30, 2025

Sheet Metal Case: Schneider Electric Server Racks

Leverage our sheet metal fabrication technology to produce batches of critical sheet metal parts for a data armor giant, using 22% less material than the industry average.

Jun 30, 2025

Injection Molding Case: Medtronic Insulin Pump Housings

It took us just over a month to produce exquisite injection-molded crafts, and we have produced more than one million pieces so far.

Oct 29, 2025

Navigating Tariff Wars: A Strategic Guide to Sourcing Custom Machined Parts

Facing supply chain disruptions from trade conflicts? Discover how to secure reliable custom machining solutions through strategic partnerships, regional diversification, and technical collaboration. Learn about RT Manufacture's resilient approach.

Oct 15, 2025

Top 5 Trends Shaping Custom Part Manufacturing in 2024&2025

In 2024-2025, custom parts manufacturing is undergoing a tech-driven revolution, with CNC machining, sheet metal fabrication, silicone molding, and injection molding leading the transformation of how custom manufactured parts are produced.

Jun 17, 2025

Thermoforming vs. Injection Molding: Which is Best for Your Project?

Compare thermoforming vs injection molding for custom parts—learn key differences in process, cost, materials, and applications (medical, automotive). Find the right method for your project.

Jun 12, 2025

The Future of Injection Molding Technology: From Home Appliances to Aerospace

This blog explores the key trends shaping the future of injection molding, how they’re tailored to home appliances and aerospace, and what custom parts manufacturers need to know to stay ahead.

Mar 22, 2025

Aluminum vs. Stainless Steel: Choosing the Right Material for CNC Custom Parts

Compare aluminum (6061-t6, 7075-t6 alloy) vs. stainless steel (304, 316) for CNC custom parts. Learn about machinability, corrosion resistance, cost, and uses (aerospace, medical).

Jun 17, 2025

Designing for CNC Machining: Tips for Precision and Efficiency

Learn how to optimize your designs for CNC machining to reduce costs and improve quality.

Jul 24, 2025

With the continuous innovation of society and technology, the demand for skilled CNC operators in the manufacturing industry will continue to grow.

Jul 24, 2025

CNC Guide: What is CNC Milling?

If technology is always improving, then CNC milling will never stop. In today's society, many products we use in our lives are inseparable from CNC milling.

Jul 24, 2025

CNC turning is an indispensable part of CNC machining. In this article, we will conduct an in-depth discussion to give everyone a clear understanding of CNC turning.

Oct 16, 2025

Thermoforming vs. Injection Molding: Choosing the Right Solution for Custom Plastic Projects

This guide breaks down exactly how the thermoforming & injection molding process works and how to choose the right one for your work.

Jul 24, 2025

Thermoforming Technology Explained: A Comprehensive Guide from Principles to Applications

In modern manufacturing, thermoforming stands out as a highly efficient and adaptable plastic processing technique. From transparent food containers in supermarkets to intricately designed automotive dashboards, this technology plays a pivotal role. As a parts manufacturer specializing in vacuum forming, we invite you to explore how thermoforming transforms ordinary plastic sheets into versatile, functional products.

Jul 24, 2025

This blog will delve into the details of vacuum casting, its workflow, types, materials, etc. Let you understand this special process of vacuum casting.

Jun 17, 2025

Vacuum Casting for Prototyping: Why It's a Game-Changer

Discover why vacuum casting is a game-changer for prototyping. Our guide covers the vacuum casting process, benefits of polyurethane vacuum casting, and how to choose a service for high-quality prototypes.

Jul 24, 2025

In this blog, we will explore the complexity of injection molding, its principles, processes, materials, applications, and more. Click to see more.

Jun 17, 2025

Injection Molding for High-Volume Production: What You Need to Know

Learn how to optimize high volume injection molding—from simulation and tolerances to surface finish and system design. Partner with the best injection molding company for scalable success.

Jul 24, 2025

With the continuous development of social progress, in the modern sheet metal processing industry, metal stamping technology can be said to be rich and colorful.

Jul 24, 2025

In sheet metal manufacturing, metal can be cut. In addition to several common cutting processes, there is also a more common and special cutting process - the sheet metal shearing process.

Jul 24, 2025

In the field of manufacturing and processing, sheet metal cutting plays a vital role. It can be said that the sheet metal cutting step is the most basic operation in manufacturing sheet metal parts.

Our Other Manufacturing Capabilities

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us