Language

20% off your first order. Save up to $1,000/€1,000. Ends 31 Dec 2024.

IATF16949:2016

ISO13485:2016

ISO9001:2015

Call Us 24/7

+86 135 1000 5651

Send Mail Us

Language

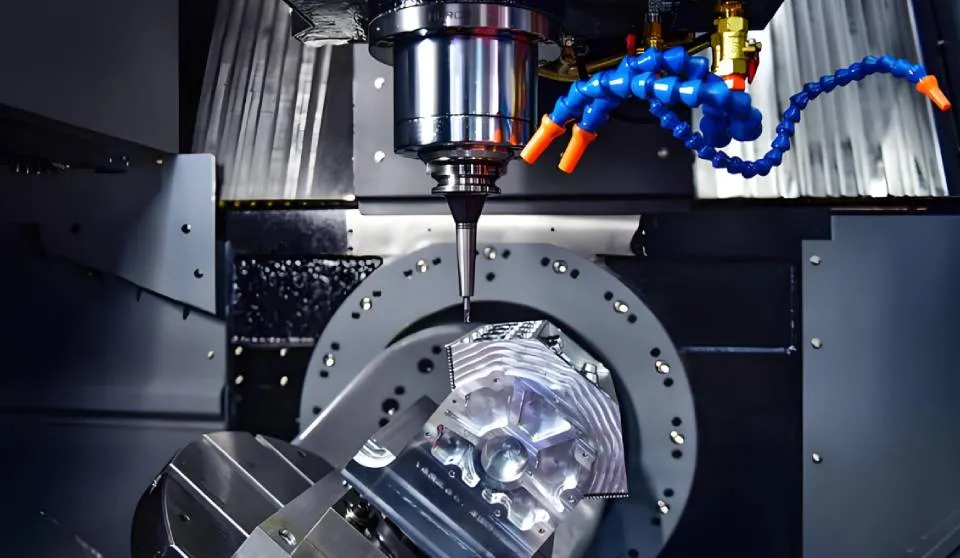

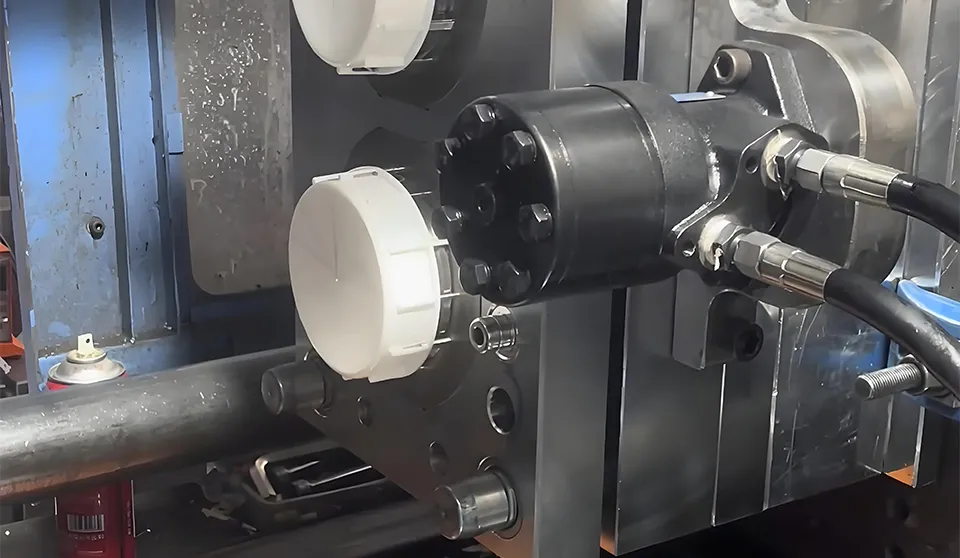

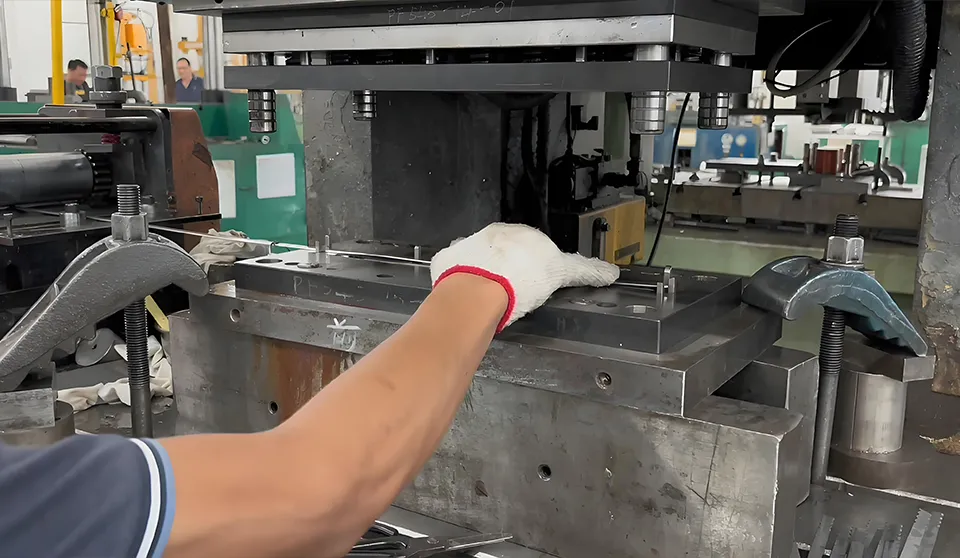

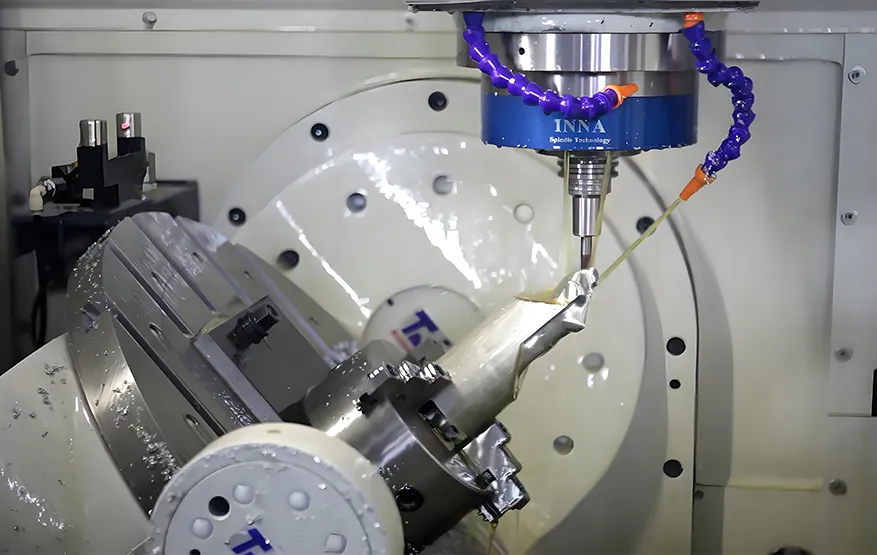

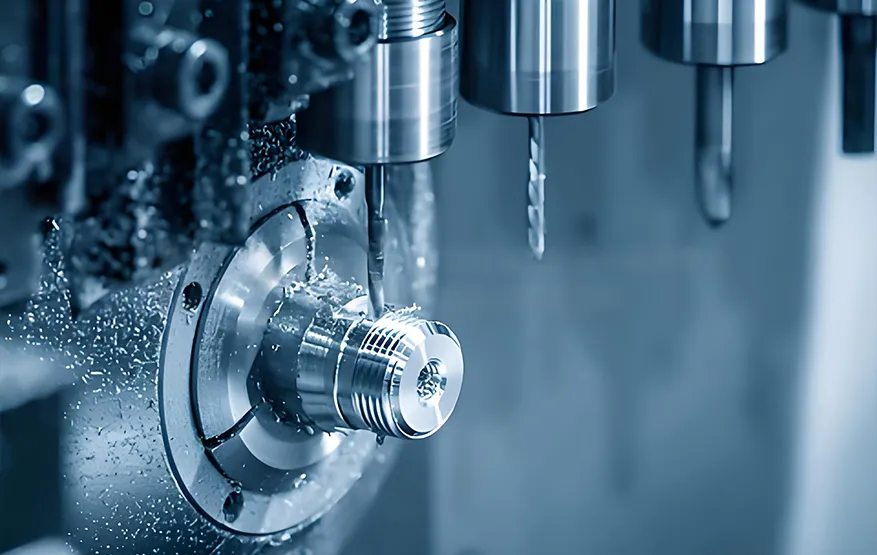

Our CNC Machining Service Solutions

At RT, we have a complete range of CNC machined parts manufacturing services. We can provide you with affordable CNC manufacturing solutions. Whether you are looking for CNC milling or turning services, we can realize your actual part-project production needs.

Compared to other parts manufacturers, our minimum tolerance accuracy can reach ±0.0003 inches (±0.010 mm) while maintaining consistent part quality.

CNC Milling

Order High-Quality CNC Milling Parts from RT Manufacture

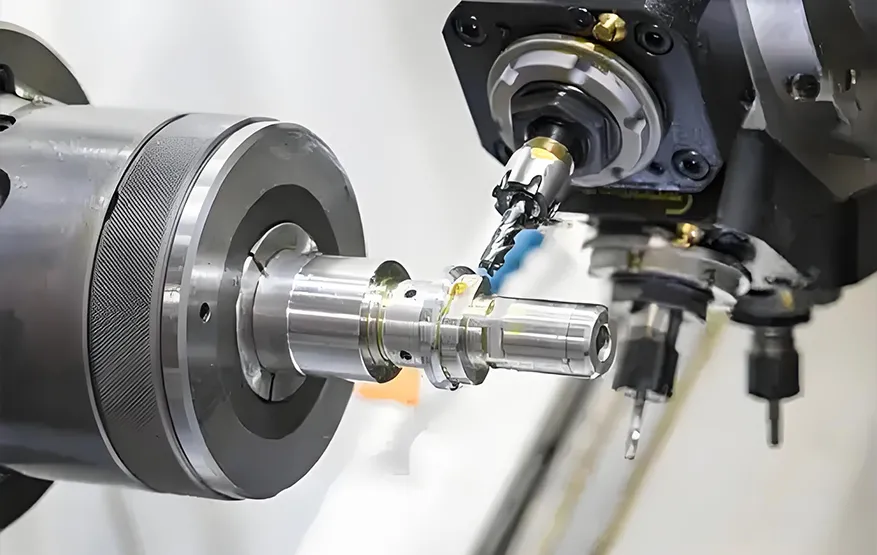

CNC Turning

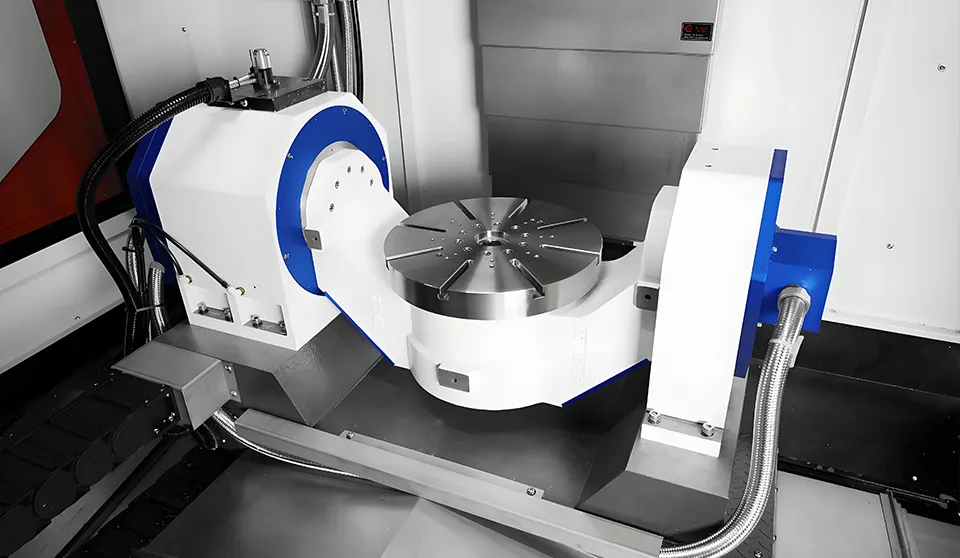

We have dozens of 3-axis, 4-axis, and 5-axis CNC machines, including standard 3-axis and 4-axis milling machines, indexed 3+2-axis milling machines, and fully automatic 5-axis milling machines. Suitable for a variety of simple or complex CNC part geometries.

5-axis CNC Machining

Multi-axis linkage: It can realize the simultaneous movement of 5 coordinate axes, making it more flexible to process complex curved surfaces, reducing the number of clamping times, and improving machining accuracy and efficiency.

Swiss Machining

Exquisite craftsmanship: Inheriting the traditional Swiss precision manufacturing technology, strictly controlling each processing link to ensure excellent product quality.

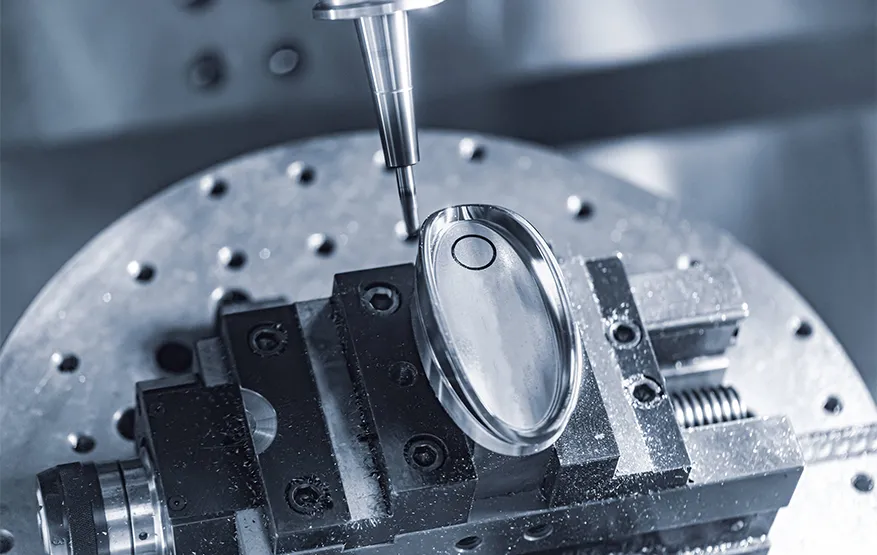

Precision CNC Machining

CNC precision: Through digital program control of the processing process, accurate positioning, high repetition accuracy, and automated mass production can be achieved.

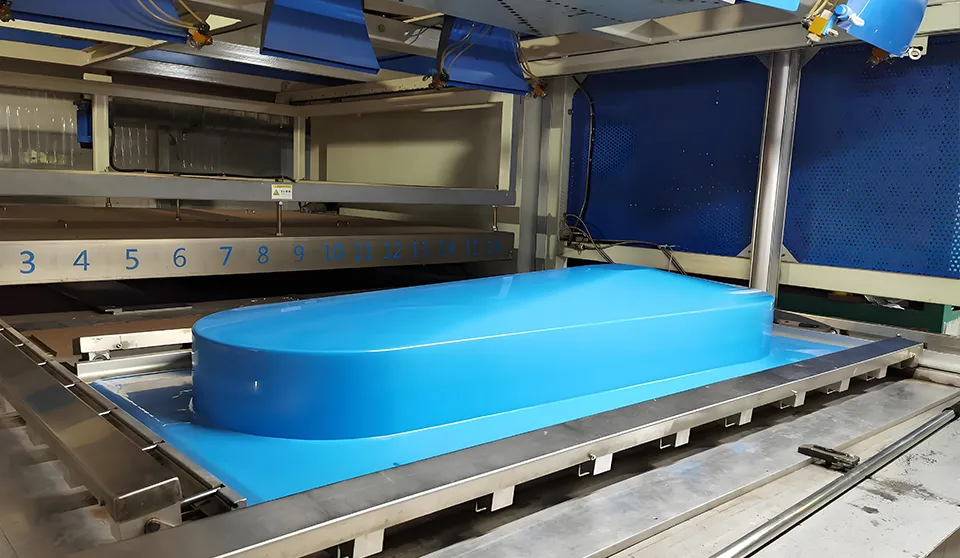

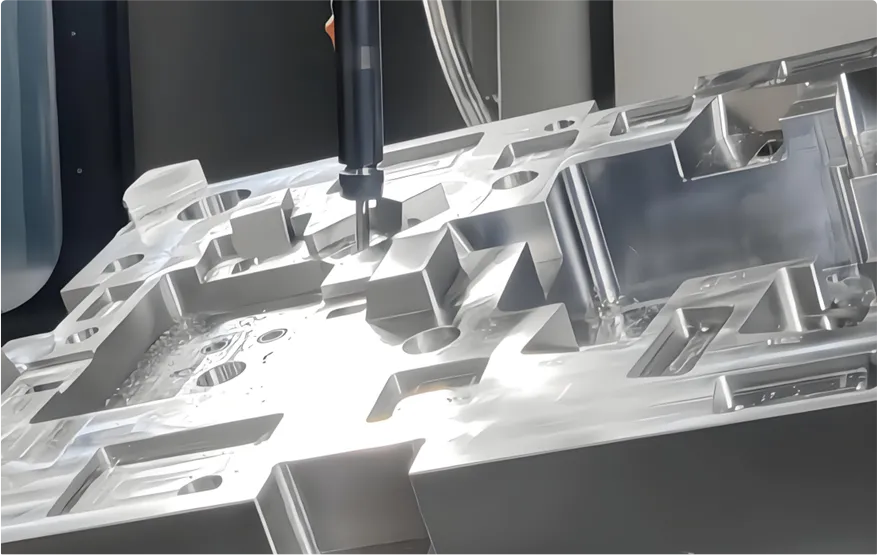

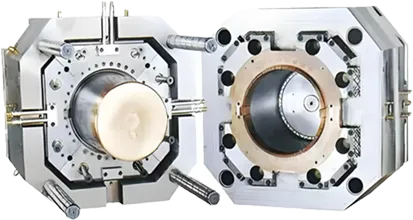

Aluminum Alloy Vacuum Forming Molds

We professionally manufacture aluminum alloy vacuum forming molds, using high-precision CNC machining. Suitable for automotive interiors, appliance housings, medical equipment, and other fields.

Our CNC Machining Materials

RT offers a wide variety of CNC machining materials. We can provide you with almost any raw material you can name in the CNC manufacturing industry (whether it is metal or plastic). Of course, you can also choose to provide the raw materials yourself and we will take care of the processing.

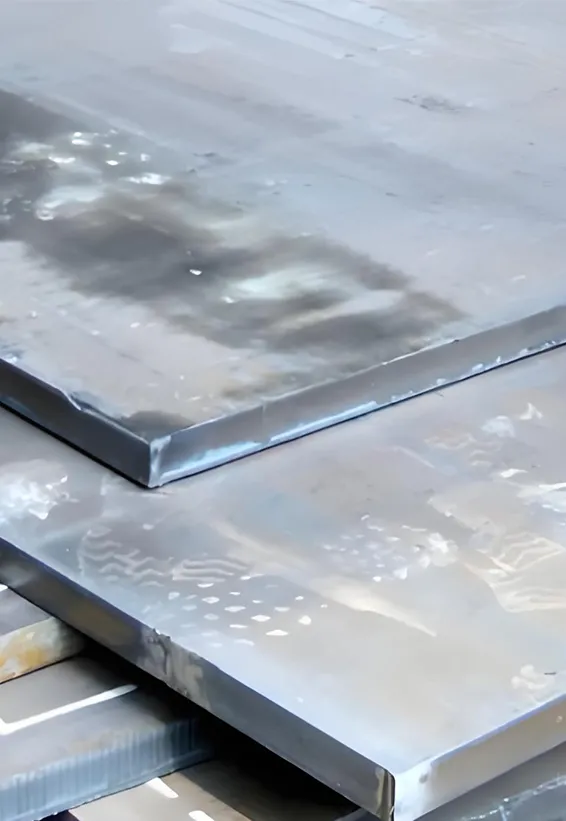

Metal

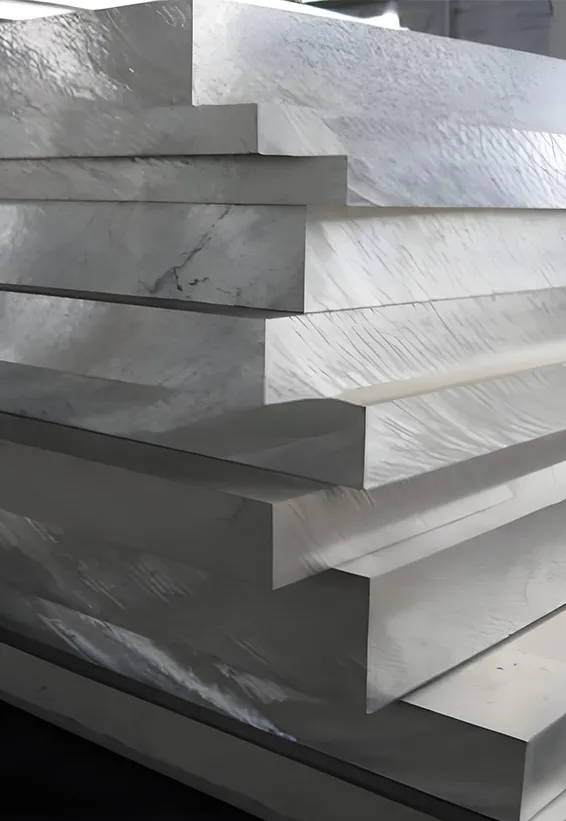

Aluminum

Copper

Stainless Steel

Tool steel

Low Carbon Steel

Zinc Alloy

Magnesium Alloy

Aluminum

The most common manufacturing material in mechanical processing is generally in alloy form. It has low density, good mechanical properties, corrosion resistance, and good conductivity, and is widely used in various fields.

Machining Time

3-5 days at the fastest

Common Aluminum Alloy Types

Industrial pure aluminum: 1060, 1050 (1050A)

Duraluminum: 2024

Rust-proof aluminum: LF21 (3003), LF2 (5052), LF4 (5083)

Aluminum-magnesium-silicon alloy (cold-treated forged aluminum alloy): 6061 (6061-T6, 6061-T651), 6063, 6082

High-strength aluminum alloy: 7075 (7A09/7075-T6)

Super-hard aluminum: MIC6

Surface Treatment Options

Polishing, glass bead blasting, powder coating, anodizing, nickel plating, chrome plating, brushing, electroplating, etc.

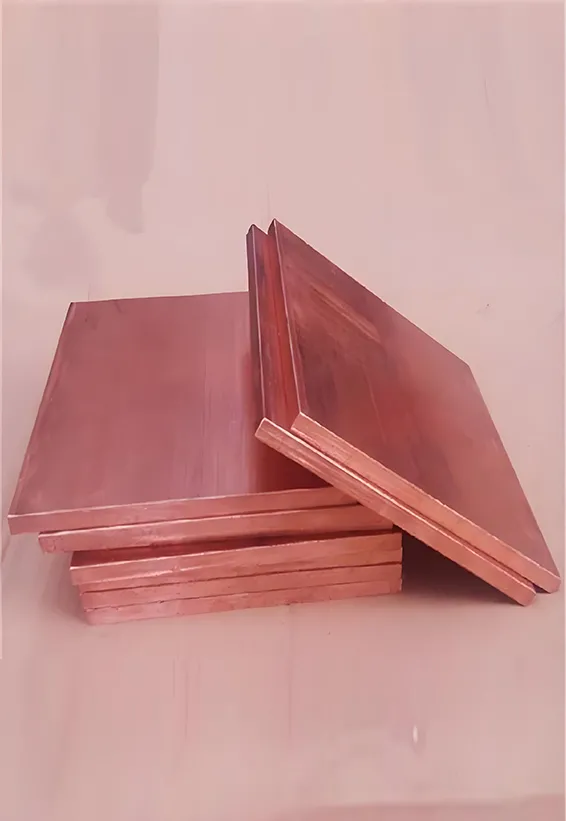

Copper

Copper is a metal with good softness, strong thermal conductivity, and high electrical conductivity. The single substance is purple-red, but the surface has a red-orange metallic luster. In CNC processing, copper alloys are often used as raw materials for manufacturing electronic components due to their excellent mechanical properties.

Machining Time:

3-5 days at the fastest

Common types of copper alloys:

Brass: H90, H80, H65, H70, HAl77-2, HSn70-1, C2600, HPb59-, HAl60-1-1, HSn62-1.

Bronze: ZCuSn6Zn6Pb3, ZCuSn10Pb5, ZCuSn5Zn5Pb5, C93200, Pb15Sn7, Pb20Sn5, Pb10Sn10, ZCuAl10Fe3, ZCuAl10Fe3Mn2, ZCuAl9Fe4Ni4Mn2.

White copper: B10, B30.

Chrome zirconium copper: C18150, C18200.

Oxygen-free copper (TU2): The oxygen content and impurity content are extremely low, and the purity is as high as 99.95% or more. TU2 oxygen-free copper has excellent electrical conductivity, thermal conductivity, and processing performance.

Stainless Steel

Stainless steel is a type of steel that is both stainless and corrosion-resistant, with good corrosion resistance and high hardness. The corrosion resistance of stainless steel mainly comes from the chromium-rich oxide film (passivation film) formed on its surface, which can effectively prevent further corrosion of the steel.

Machining Time:

5 days at the fastest

Common types of stainless steel:

Ferritic stainless steel: 405, 400, 409, 430, 434, 439, 442, 446, 00Cr30Mo2

Austenitic stainless steel: 303, 304, 316, 321, 904L, 2205

Austenitic-ferritic duplex stainless steel: 022Cr23Ni5Mo3N (S2205), 022Cr22Ni5Mo 3N (S2225), 1.4410 (S32750), 022Cr19Ni5Mo3Si2N (S21953), 022Cr17Ni12Mo2 (S21860)

Martensitic stainless steel: 2Cr13, 3Cr13, 4Cr13, 20Cr13, 30Cr13, 68Cr17, 1Cr13, 7Cr17, 12Cr13, 1Cr12, 440C, 9Cr18Mo, 431.

Surface Treatment Options:

Blackening, electrolytic polishing, sandblasting, passivation, electroplating, powder coating, galvanizing, screen printing, etc.

Tool steel

Tool steel is a kind of steel with high hardness and strong wear resistance. Tool steel is generally divided into carbon tool steel, alloy tool steel, and high-speed tool steel.

Machining Time:

6 days at the fastest

Common stainless steel grades:

45 steel, Cr12 steel, W18Cr4V steel, H13 steel, P20 steel, D2 steel

Surface Treatment Methods:

Quenching, low temperature tempering, sandblasting, polishing, blackening, powder spraying

Low Carbon Steel

Low-carbon steel, also known as mild steel, is a carbon steel with low strength but good plasticity and toughness. It also has good cold formability and weldability.

Low-carbon steel can be divided into ordinary low-carbon steel plates and special steel plates, including low-alloy high-strength steel and corrosion-resistant and heat-resistant composite steel plates. Ordinary low-carbon steel plates are divided into cold-rolling and hot-rolling. Cold-rolled steel plates are mostly used to manufacture automobile bodies, and hot-rolled plates are mostly used to manufacture frames.

Machining Time:

6 days at the fastest

Common carbon steel grades:

DC01, DC03, DC04, DC05, DC06, DC07

Finishing options:

Polishing, blackening, quenching, spraying, etc.

Zinc Alloy

Zinc alloy is an alloy composed of zinc and other elements. Common alloying elements include aluminum, copper, magnesium, cadmium, lead, titanium, etc. Zinc alloy has the characteristics of low melting point, easy welding, corrosion resistance, and good processing performance.

Machining Time:

5 days at the fastest

Common types of zinc alloys:

Zinc-aluminum alloy, zinc-copper alloy, zinc-lead alloy, aluminum-zinc alloy, copper-zinc alloy, titanium-zinc alloy, magnesium-zinc alloy, zinc-aluminum alloy, ZnCu1.5, ZnCu1.2, ZnCu1, ZnCu0.3

Surface Treatment Methods:

Electroplating, spraying, galvanizing, oxidation, polishing, etc.

Magnesium Alloy

Magnesium alloy is an alloy composed of magnesium and other elements. Magnesium alloy has the characteristics of low density (about 1.8g/cm³), high strength, large elastic modulus, good heat dissipation, and good shock absorption.

Its main alloying elements are aluminum, zinc, manganese, cerium, thorium, etc. The most widely used is magnesium-aluminum alloy, followed by magnesium-manganese alloy and magnesium-zinc-zirconium alloy. Magnesium alloy is widely used in aviation, aerospace, transportation, chemical industry, rocket, and other industrial sectors.

Machining Time:

5-7 days at the fastest

Common magnesium alloy grades:

AZ31B, AZ91D, AZ61M, ZK60, ZK61S, WE43, WE54, WE94, AM50A, AM60B, M1C, M2M, M2S, ME20M, WE43, WE54, WE94

Surface treatment methods:

anodizing, electroplating, chemical plating, pickling, passivation, surface spraying, sandblasting, etc.

Plastic

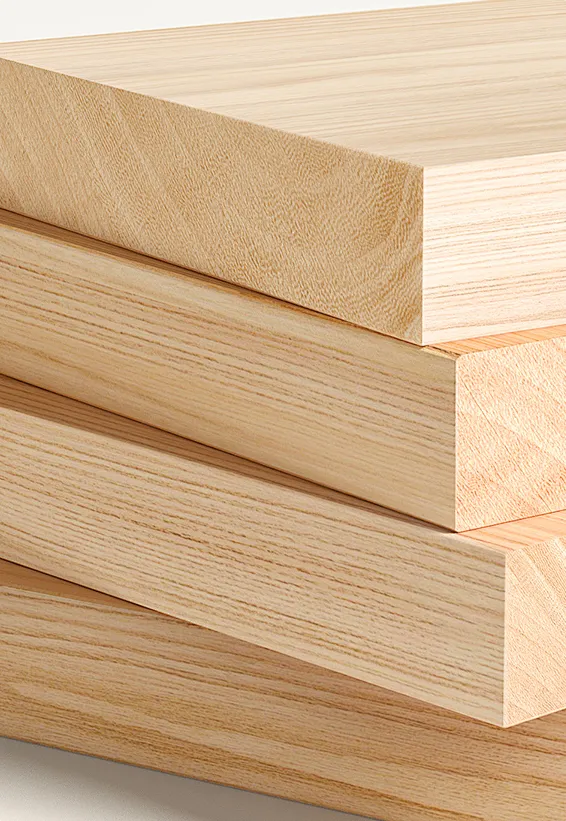

Wood

Wood

Wood

There are two types of wood materials required for CNC machining: hardwood and softwood. Hardwood is one of the most suitable woods for CNC engraving machine processing. It is hard, dense, delicate, wear-resistant, and not easy to deform. Softwood is soft, loose, light, easy to cut, and has a certain toughness.

Machining Time:

5 days at the fastest

Common Wood Types:

Teak, rosewood, walnut, oak, pine, cedar, white pine

Surface Treatment Options:

Painting, baking, powder spraying, sandblasting, shot peening, electrophoresis, silk screen printing, brushing, dyeing

Put Your Parts Into Production Today

Our CNC Machining Surface Finishes

We offer you a range of extreme CNC part surface finishes. You can choose your desired post-processing process from the following CNC surfaces. Whether it is sandblasting, anodizing, or electroplating, we can ensure that your CNC parts meet both aesthetic and functional specifications.

Using compressed air as power, the high-speed jet beam sprays abrasives onto the workpiece's surface so that the workpiece's surface can obtain a certain degree of cleanliness and different roughness, thereby improving the mechanical properties of the surface of the workpiece.

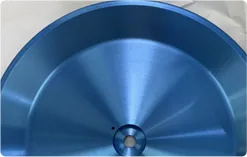

Anodizing can significantly improve the wear and corrosion resistance of CNC metal parts while also increasing their aesthetics and lifespan.

Polishing can reduce the surface roughness of CNC workpieces and obtain a bright and smooth surface. It is mainly used to improve the appearance and texture of the workpiece surface and is sometimes used to eliminate gloss.

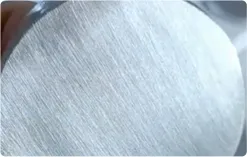

The brushed process can break through the limitations of material use and meet more creative needs. Grinding products form lines on the surface of the workpiece, which not only has a decorative effect and anti-rust, anti-oxidation, anti-scratch, and other properties.

The passivation process can form a protective film on the metal surface, thereby slowing down the corrosion rate of the metal. Improve the corrosion resistance of CNC metal and prevent surface contamination.

"Blackening" is also called bluing. This process is mainly used in steel materials. It can not only enhance the corrosion resistance of the metal and extend its service life, but also give the product a uniform black appearance and improve its aesthetics.

The electrolytic polishing process is a polishing technology that uses the principle of electrolysis to selectively remove the rough parts of the metal surface, thereby improving the smoothness of the part surface.

Electroplating is bonding a metal layer to a CNC part to protect it from oxidation (such as rust), thereby improving the part's wear resistance, conductivity, light reflectivity, and corrosion resistance, and enhancing aesthetics.

Chemical plating is a method of coating the surface of materials through chemical reactions. Compared with traditional coating methods such as electroplating and hot-dip galvanizing, chemical plating has better uniformity, precision, and contact.

Heat treatment is a comprehensive process that changes the material structure through heating, insulation, and cooling steps, thereby affecting the mechanical properties, corrosion resistance, and other physical properties of the material.

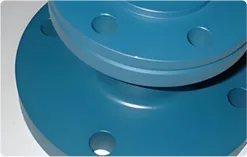

Powder spraying is a post-processing process that utilizes the corona discharge phenomenon to evenly adsorb powder coating onto the surface of the workpiece, and then form a continuous, flat, and smooth coating after high-temperature baking.

The Teflon spraying process has excellent properties such as chemical corrosion resistance, non-stick, high-temperature resistance, and long service life. Teflon coating is almost insoluble in all solvents, so it is called "non-stick coating".

The screen printing process has the characteristics of strong adaptability, simple process, high production efficiency, and low cost. Its application fields are very wide, including plastic printing, metal printing, ceramic printing, glass printing, electronic product printing, and so on.

The electrophoresis process is mainly used for corrosion protection and decoration of metal surfaces. The paint particles suspended in the solution are attracted by the electric current and deposited on the surface of the substrate to form a protective film.

Diamond-like carbon coating is an amorphous film composed of carbon elements, which have high hardness, high elastic modulus, low friction coefficient, wear resistance, and good vacuum friction characteristics. It is usually used as a wear-resistant coating and has a wide range of applications in the industrial field, especially in situations requiring high hardness, low friction, and wear resistance.

CNC Machining Tolerances

Our CNC machine tolerance is so precise, that every CNC part RT manufactures will fit consistently and perfectly with the other parts.

| Description | |||||||||

| CNC Tolerances | General Tolerances | Precision Tolerances | Min Wall Thickness | Min End Mill Size | Min Drill Size | Maximum Part Size | Minimum Part Size | Production Volume | / |

CNC Metals: ISO 2768-m CNC Plastics: ISO 2768-c | We can produce and examine components with precise tolerances based on your design specifications and GD&T annotations, including tolerances as tight as +O.0003 inches. | 0.3-0.5mm | 0.1mm | 0.5mm | CNC Milling: 3500x2500x1200 mm CNC Turning: 250x550 mm | CNC Milling: 2x3 x3 mm CNC Turning: 1x1 mm | Prototoyping: 1-100 pcs Low volume: 101-10,000 pcs High volume: 10000+ pcs | / | |

| Linear dimension range(mm) | |||||||||

| Geometric Characteristics | Symbol | 0.5 – 3 | >3 – 6 | >6 – 30 | >30 – 120 | >120 – 400 | >400 – 1000 | >1k – 2k | |

| Dimension | Length |  | ±0.01 | ± 0.01 | ± 0.02 | ± 0.03 | ± 0.05 | ± 0.05 | ± 0.1 - ± 0.5 |

| Diameter |  | 0.006 | 0.008 | 0.01 | 0.015 | 0.02 | / | / | |

| Angle |  | ± 0.03 | ± 0.04 | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.15 | / | |

| Form | Straightness |  | 0.003 | 0.004 | 0.005 | 0.005 | 0.01 | 0.02 | / |

| Flatness |  | 0.001 | 0.002 | 0.003 | 0.01 | 0.03 | 0.05 | / | |

| Orientation | Parallelism |  | 0.003 | 0.003 | 0.003 | 0.01 | 0.05 | 0.1 | / |

| Perpendicularity |  | 0.003 | 0.004 | 0.005 | 0.01 | 0.05 | 0.1 | / | |

| Location | Position |  | 0.01 | 0.02 | 0.02 | 0.02 | 0.05 | 0.1 | 0.2 |

| Concentricity |  | 0.03 | 0.03 | 0.05 | 0.01 | 0.05 | / | / | |

*Please clearly indicate tolerances for nominal sizes below 0.1mm on your technical drawing.

Scientific CNC Machining Service Quality Management

After years of exploration and practice, we have formed our own parts management system. The CNC parts produced through our "three-step" quality process are deeply appreciated by every customer.

Before CNC Machining

Personnel management: train operators, programmers, and quality inspectors, and certify their qualifications.

Equipment management: select equipment according to processing requirements, formulate maintenance plans, and ensure accuracy.

Raw material management: inspect chemical composition, mechanical properties, etc., and control suppliers.

Process management: reasonably prepare process documents and strictly review them.

During CNC Machining

Program and first-piece management: verify the program with simulation software and strictly inspect the first piece.

Tool management: monitor tool wear, replace it in time, and record usage.

Parameter management: optimize cutting parameters according to machining factors and make fine adjustments in time.

Inspection and feedback management: use online inspection equipment to provide timely feedback on quality issues.

After CNC Machining

Finished product management: conduct comprehensive inspections according to standards and handle unqualified products.

Traceability management: establish a system to record quality information at all stages.

Customer management: collect feedback, and handle quality issues and feedback results.

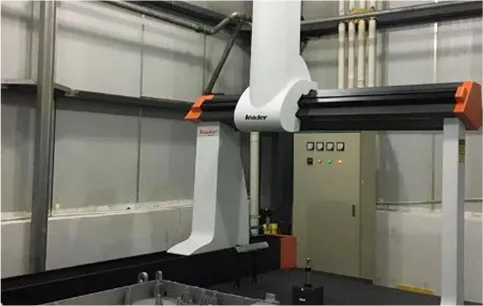

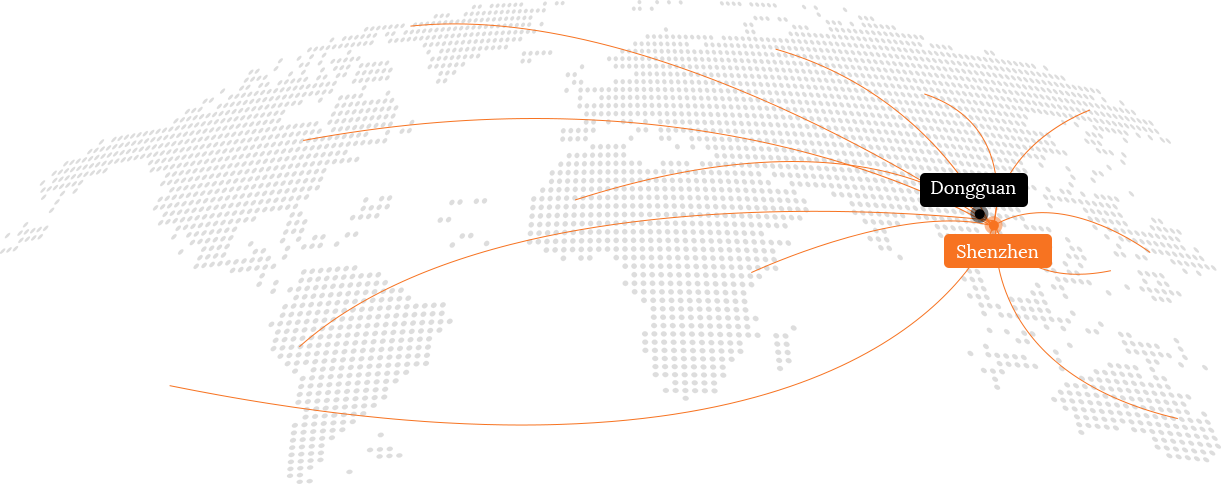

Our CNC Machine Shop | CNC Manufacturing Equipment

We have extensive CNC manufacturing capabilities and can provide you with various CNC machining services. At RT Manufacturing, the machine shop machines include a variety of automatic lathes, CNC lathes, and CNC milling machines, as well as a variety of grinders, EDMs, and other auxiliary equipment.

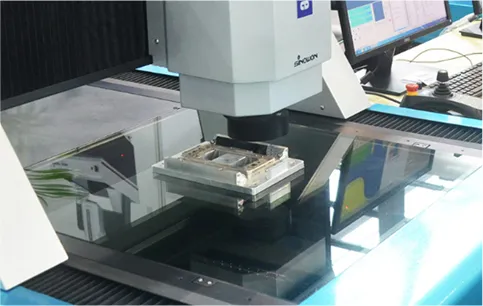

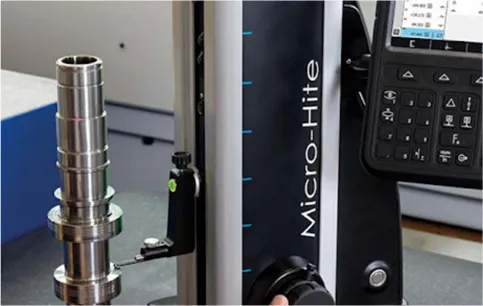

CNC Testing Equipment

At RT, we have a range of testing equipment and every manufactured part is rigorously quality tested to ensure consistent quality of CNC parts.

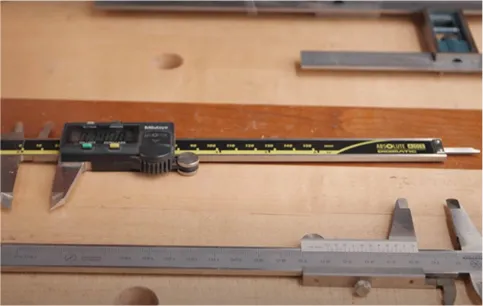

Caliper

In CNC machining, calipers can be used to measure the linear dimensions of parts, such as length, width, thickness, etc., with an accuracy of 0.02mm or even higher. They are basic and commonly used detection tools.

Micrometer

Micrometer, also known as screw micrometer, is mainly used to measure high-precision outer diameter dimensions. The measurement accuracy can reach 0.01mm. In scenarios such as CNC machining to detect the outer diameter of shaft parts, micrometers can provide high-precision measurement data to ensure that the part size meets the design requirements.

Three-coordinate measuring machine

The three-coordinate measuring machine can measure parts in three dimensions and can accurately measure the dimensions, form, and position tolerances of various complex shapes. It is widely used in the detection of complex molds, precision parts, etc., and the measurement accuracy can reach a micron level.

Thread gauge

Thread gauges are divided into thread plug gauges and thread ring gauges, which are used to detect the size and accuracy of threads. Thread plug gauges are used to detect internal threads and thread ring gauges are used to detect external threads. Screwing the thread gauge with the processed thread and judging whether the thread is qualified according to the screwing condition is indispensable in the quality inspection of thread machining.

Two-dimensional image measuring instrument

The two-dimensional image measuring instrument obtains the image of the part through a high-resolution optical lens, then uses the image processing algorithm to accurately measure the two-dimensional dimensions of the part, such as length, width, diameter, angle, etc. It performs well in detecting small precision parts in CNC machining, and the detection accuracy can reach a micron level, greatly improving the detection efficiency and accuracy.

Height gauge

The height gauge is a measuring tool for measuring the workpiece's height size and relative position. With a high-precision measuring head, the height of the part, the step height difference, etc. can be accurately measured by moving the measuring slide. In CNC machining, it is often used to detect the thickness of flat parts and the height difference between different planes. The measurement accuracy can usually reach 0.01mm, providing key data for part assembly and quality control.

Visit Our Machine Shop

Take a video tour of our 3000 square meter CNC manufacturing shop and see how we quickly manufacture parts daily.

What Is Included In The Online CNC Quote?

Upload the 3D CAD file of your machined part and we will send you a CNC manufacturing quote within a few hours. If the file contains an unreasonable part structure, we will provide you with valuable suggestions. You can always modify the material or quantity in the quote before placing an order.

Click to upload

STEP | STP | STL | DXF | IGS | X_T | X_B

Max.file size:<15MB

All uploads are secure and confidential.

What Is CNC Machining Service?

CNC machining service is an advanced manufacturing method that uses digital control systems to accurately control machine tools for part machining. By converting the designed part drawings into digital program codes and inputting them into CNC machine tools, the machine tools can automatically and accurately complete a series of machining operations such as cutting, drilling, milling, grinding, etc. according to these instructions. This machining process is highly automated, greatly reducing human intervention and ensuring the stability of machining accuracy and quality.

Advantages of CNC Machining Services

Highest Standards of Quality Control

IATF16949:2016

ISO13485:2016

ISO9001:2015

High precision

CNC machining can achieve extremely precise dimensional control, and the tolerance range can be accurate to the micron level. This makes the parts produced highly consistent and can meet the needs of industries with demanding precision, such as aerospace, medical equipment, etc.

High efficiency

CNC machine tools can run continuously and uninterruptedly, and can quickly switch tools and machining parameters during the machining process, greatly shortening the machining time of a single part and improving overall production efficiency. At the same time, the automated machining process reduces manual operation and waiting time, further improving production capacity.

Flexibility

Modify the CNC program to easily achieve the machining of different parts without large-scale readjustment of the machine tool. This makes small-batch, multi-variety production efficient and economical, and can quickly respond to the market's diverse needs.

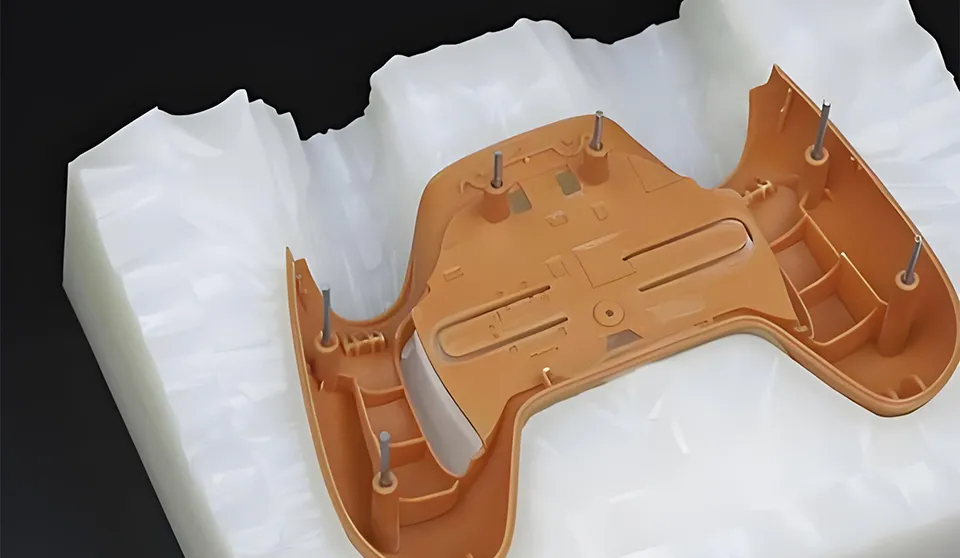

Complex shape processing capabilities

CNC machining can complete the processing of parts with complex geometric shapes, such as aircraft engine blades with free-form surfaces, molds with complex cavities, etc. Traditional processing methods make These complex shapes difficult to achieve, but CNC machining technology can perfectly handle them.

CNC Machining Application Areas

There are many application scenarios for CNC machining. The following are the most common ones in our lives

Automobile

Medical Devices

Aerospace

Electronic Communications

Energy Industry

Industrial Equipment Field

Lighting

Automobile

In the field of automobile manufacturing, CNC machining is used to manufacture automobile parts, frames, body panels, etc. High-precision CNC machining helps improve automobile performance and quality while meeting the needs of large-scale production.

Medical Devices

In the medical device industry, CNC machining is used to manufacture artificial joints, dental implants, surgical instruments, etc. High-precision machining ensures the good compatibility and safety of these instruments with human tissues.

Aerospace

In the field of aerospace, CNC machining is used to manufacture aircraft engine parts, wing structural parts, satellite parts, etc. These parts have extremely high requirements for material properties and machining accuracy. CNC precision machining can ensure that they meet the requirements of high strength, lightness, and high precision.

Electronic Communications

In the field of electronic communications, CNC machining is used to manufacture mobile phone cases, computer motherboards, chip packaging molds, etc. As electronic products develop towards miniaturization and high performance, CNC precision machining can meet their requirements for component accuracy and complex shapes.

Energy Industry

In the energy industry, CNC machining can manufacture various traditional engines and turbine components. CNC technology can ensure the machining accuracy and surface quality of parts and components, and meet their use requirements under extreme working conditions such as high temperature and high pressure.

Industrial Equipment Field

In the field of industrial equipment, there are many application scenarios for CNC machining and manufacturing. For example, most mechanical automation equipment, agricultural parts, etc. are produced through CNC machining technology.

Lighting

In the field of lighting, lighting designers can use CNC machining technology to produce accurate lighting equipment prototypes for design verification. This includes testing and evaluating the shape, size, and lighting effects of lamps.

CNC Machining Parts Gallery By RT

Our CNC prototype machining parts and their manufacturing processes.

CNC Machining FAQs

Why Choose CNC Machining?

CNC machining solutions are fast, accurate, and can produce end-use parts of any specification and quantity.

How Much Does CNC Machining Cost?

Our CNC machining costs are quoted based on specific design drawings and typically vary based on complexity, quantity, and lead time. The best way to get a price is to submit a 3D CAD model, or if you need, submit your design drawings directly to us.

What Is the Typical Lead Time for Your CNC Machining Order?

We offer a variety of lead times to fit your budget, and we can provide CNC parts in as fast as five days.

What Tolerances Can Your CNC Machine Achieve?

For most applications, our machines can achieve tight tolerances of +/- 0.0001 inches. If you need tighter tolerances for special projects, please consult us.

Do You Accept CNC Materials Provided by Customers?

Yes, if you would like to provide your own CNC materials, we can provide this manufacturing option.

Can You Accept Rush Orders or Expedited Shipments?

Speed and quality are our standards. If you require a faster delivery time for a specific quote, please contact your sales representative and we will discuss the feasibility of this solution.

How Do You Ensure the Confidentiality of Our Designs And Intellectual Property?

At RT Manufacturing, we understand the importance of information security, so we are happy to sign a non-disclosure agreement.

What Certifications or Industry Standards Do You Follow for Your CNC Machining Processes?

RT is ISO 9001 certified, ISO 13485 compliant, and has an IATF-approved manufacturing quality certification.

Do You provide CNC Drawing Design?

Currently, we do not provide this service. We only take care of the manufacturing part (you design, we make), and do not provide related drawing design services.

What Tolerance Standards Do You Guarantee?

For CNC metal machining parts, we follow the standards of ISO 2768-m (medium) or ISO 2768-f (fine). CNC plastic machining parts will follow 2768-m (medium). Our minimum geometric tolerance can be as low as ± 0004 inches (0.010 mm). Additionally, we ensure that our manufacturing partners adhere to ISO 2768 standards for all CNC machined parts.

Does RT Manufacturing Have A Minimum Order Quantity (MOQ) for CNC Machining?

At RT, we are about only producing as many orders as our customers require. Therefore, we do not set minimum order quantities. On the other hand, we always provide the highest level of service to our customers, ensuring customized solutions from single-piece prototype manufacturing to mass production to meet each customer's needs.

See What Our Customers Say to Us

Reviews Speak Louder Than Words - Real Customer Reviews

CNC Machining Resources

Blogs

News

Case Studies

Guidelines

Materials

Design Guides

CNC Machining

Thermoforming

Vacuum Casting

Injection Molding

Sheet Metal Fabrication

Oct 15, 2025

What is Teflon surface treatment?

In this article, we'll break down each step of the Teflon process, detail which materials can (and can't) be Teflon-coated, and explain why this treatment technique changes the game for part surfaces.

Jul 24, 2025

That unassuming "right angle" marked on your issued drawing could secretly plant the seeds of product failure, cost explosions, or even customer claims.

Apr 20, 2025

How Does CNC Machining Drive Innovation in Automotive Parts Manufacturing?

CNC machining, with its high precision and efficiency, is reshaping the automotive parts manufacturing industry. This article will explore the applications of CNC milling and turning in the automotive sector and how they help manufacturers achieve lighter, more durable components.

Oct 29, 2025

Global Supply Chain Shifts: How Chinese Machining Suppliers Deliver Value and Reliability

Explore how China's machining sector combines advanced technology with supply chain resilience to provide precision parts and custom machining solutions in evolving global markets.

Oct 22, 2025

How Custom Part Manufacturing is Revolutionizing the Medical Equipment Industry

In the ever-evolving landscape of healthcare, medical equipment stands as the backbone of moder diagnosis and treatment.

Jun 12, 2025

The Key Role of Sheet Metal Processing in Home Appliance Manufacturing

This blog breaks down how sheet metal processing—and its related techniques like sheet metal manufacturing shape the appliances we use every day, and why it’s irreplaceable in appliance production.

Jun 30, 2025

CNC Machining Case: DJI Drone Motor Mounts

Learn about our exciting story of drone manufacturing with DJI Innovations. Our large-scale aerospace precision manufacturing can achieve monthly batch production of up to tens of thousands of units.

Jun 30, 2025

Sheet Metal Case: Schneider Electric Server Racks

Leverage our sheet metal fabrication technology to produce batches of critical sheet metal parts for a data armor giant, using 22% less material than the industry average.

Jun 30, 2025

Injection Molding Case: Medtronic Insulin Pump Housings

It took us just over a month to produce exquisite injection-molded crafts, and we have produced more than one million pieces so far.

Oct 29, 2025

Navigating Tariff Wars: A Strategic Guide to Sourcing Custom Machined Parts

Facing supply chain disruptions from trade conflicts? Discover how to secure reliable custom machining solutions through strategic partnerships, regional diversification, and technical collaboration. Learn about RT Manufacture's resilient approach.

Oct 15, 2025

Top 5 Trends Shaping Custom Part Manufacturing in 2024&2025

In 2024-2025, custom parts manufacturing is undergoing a tech-driven revolution, with CNC machining, sheet metal fabrication, silicone molding, and injection molding leading the transformation of how custom manufactured parts are produced.

Jun 17, 2025

Thermoforming vs. Injection Molding: Which is Best for Your Project?

Compare thermoforming vs injection molding for custom parts—learn key differences in process, cost, materials, and applications (medical, automotive). Find the right method for your project.

Jun 12, 2025

The Future of Injection Molding Technology: From Home Appliances to Aerospace

This blog explores the key trends shaping the future of injection molding, how they’re tailored to home appliances and aerospace, and what custom parts manufacturers need to know to stay ahead.

Mar 22, 2025

Aluminum vs. Stainless Steel: Choosing the Right Material for CNC Custom Parts

Compare aluminum (6061-t6, 7075-t6 alloy) vs. stainless steel (304, 316) for CNC custom parts. Learn about machinability, corrosion resistance, cost, and uses (aerospace, medical).

Jun 17, 2025

Designing for CNC Machining: Tips for Precision and Efficiency

Learn how to optimize your designs for CNC machining to reduce costs and improve quality.

Jul 24, 2025

With the continuous innovation of society and technology, the demand for skilled CNC operators in the manufacturing industry will continue to grow.

Jul 24, 2025

CNC Guide: What is CNC Milling?

If technology is always improving, then CNC milling will never stop. In today's society, many products we use in our lives are inseparable from CNC milling.

Jul 24, 2025

CNC turning is an indispensable part of CNC machining. In this article, we will conduct an in-depth discussion to give everyone a clear understanding of CNC turning.

Oct 16, 2025

Thermoforming vs. Injection Molding: Choosing the Right Solution for Custom Plastic Projects

This guide breaks down exactly how the thermoforming & injection molding process works and how to choose the right one for your work.

Jul 24, 2025

Thermoforming Technology Explained: A Comprehensive Guide from Principles to Applications

In modern manufacturing, thermoforming stands out as a highly efficient and adaptable plastic processing technique. From transparent food containers in supermarkets to intricately designed automotive dashboards, this technology plays a pivotal role. As a parts manufacturer specializing in vacuum forming, we invite you to explore how thermoforming transforms ordinary plastic sheets into versatile, functional products.

Jul 24, 2025

This blog will delve into the details of vacuum casting, its workflow, types, materials, etc. Let you understand this special process of vacuum casting.

Jun 17, 2025

Vacuum Casting for Prototyping: Why It's a Game-Changer

Discover why vacuum casting is a game-changer for prototyping. Our guide covers the vacuum casting process, benefits of polyurethane vacuum casting, and how to choose a service for high-quality prototypes.

Jul 24, 2025

In this blog, we will explore the complexity of injection molding, its principles, processes, materials, applications, and more. Click to see more.

Jun 17, 2025

Injection Molding for High-Volume Production: What You Need to Know

Learn how to optimize high volume injection molding—from simulation and tolerances to surface finish and system design. Partner with the best injection molding company for scalable success.

Jul 24, 2025

With the continuous development of social progress, in the modern sheet metal processing industry, metal stamping technology can be said to be rich and colorful.

Jul 24, 2025

In sheet metal manufacturing, metal can be cut. In addition to several common cutting processes, there is also a more common and special cutting process - the sheet metal shearing process.

Jul 24, 2025

In the field of manufacturing and processing, sheet metal cutting plays a vital role. It can be said that the sheet metal cutting step is the most basic operation in manufacturing sheet metal parts.

Simply upload your design files to get a detailed quote!

What Are You Waiting for?

We Are Here

Simply upload your design files to get a detailed quote!

Get In Touch With Us